In today’s industrial sector, conveyor belts play a pivotal role in streamlining processes and ensuring the smooth and efficient flow of products. Among various conveyor belt types, Plastic Conveyor Belts stand out with their unique and adaptable features, making them an attractive solution for a wide range of industries. In this comprehensive guide, we will delve deep into the world of Plastic Conveyor Belts, examining their unique benefits, potential applications across various industries, and essential maintenance practices to ensure their optimal performance and longevity.

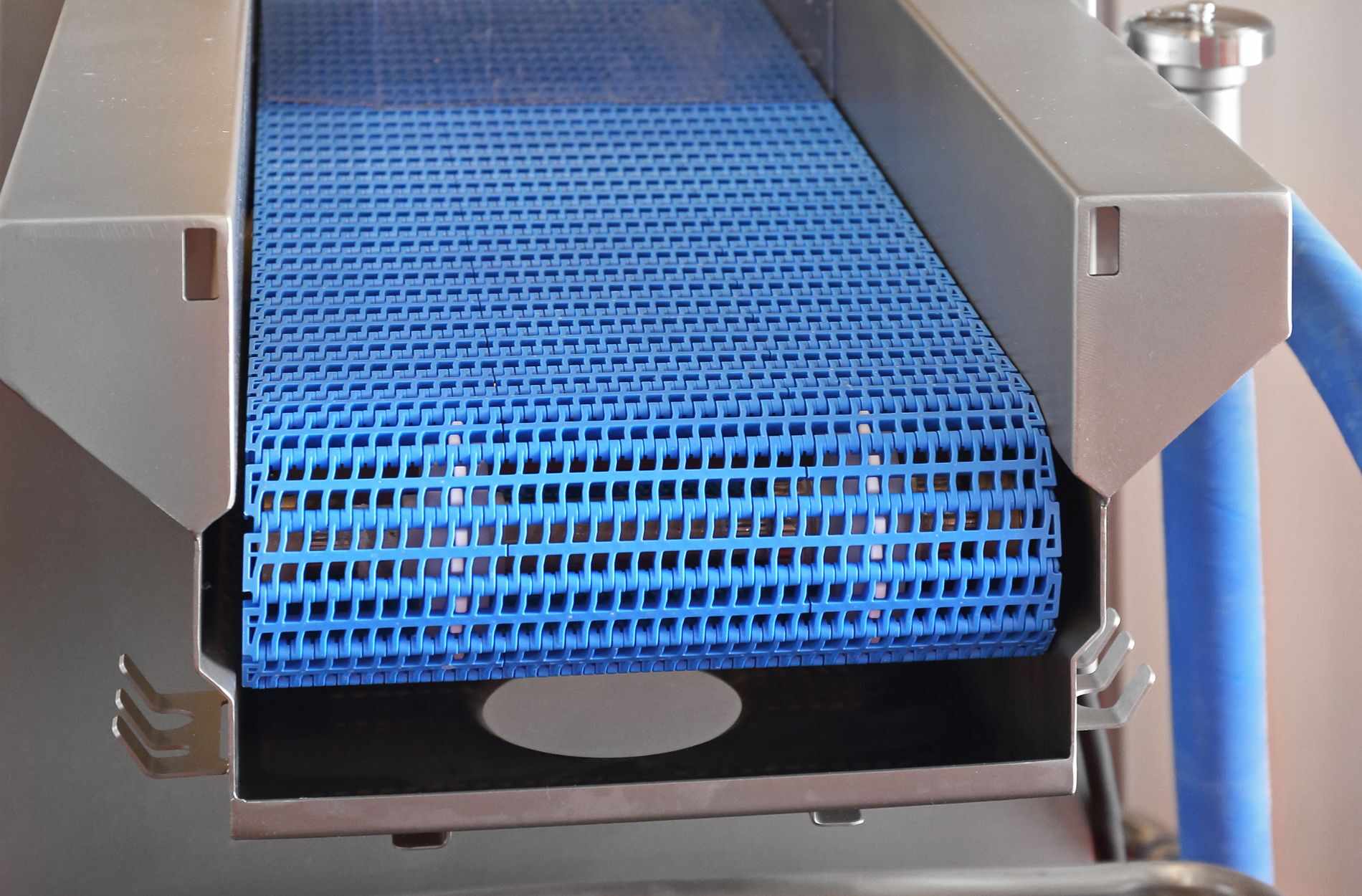

Plastic Conveyor Belts are constructed by interconnecting modular plastic components, forming a durable, yet flexible belt. This design allows them to handle various weights and sizes of products, making Plastic Conveyor Belts an excellent choice for applications in industries such as food processing, materials handling, and packaging, among others.

The inherent adaptability of Plastic Conveyor Belts not only lies in their ability to handle a variety of products but also in their customisable features, like different materials, colours, and link types. This allows for ideal performance and a tailored fit for your specific conveyor system and industry requirements. Additionally, Plastic Conveyor Belts are easy to maintain and can be quickly repaired or replaced when individual components become worn or damaged.

In this guide, we will explore the remarkable world of Plastic Conveyor Belts in more detail, providing insights into their features, suitable industries and applications, and maintenance practices necessary to ensure their performance and extended service life. With this knowledge, you can make informed decisions about whether Plastic Conveyor Belts are the right choice for your conveyor system and how to maintain them for peak efficiency.

Key Advantages and Characteristics of Plastic Conveyor Belts

Durability and Longevity

One of the primary advantages of Plastic Conveyor Belts is their outstanding durability and longevity. Constructed from high-quality, modular plastic components, these belts are both resistant to wear and easy to repair, ensuring that they can provide reliable service for extended periods.

Customisation and Versatility

Plastic Conveyor Belts offer exceptional versatility and can be customised to suit the specific needs of your conveyor system. With options like various materials, colours, and link types, these belts can be tailored to provide the ideal performance and fit for your industry requirements.

Ease of Maintenance and Repair

The modular design of Plastic Conveyor Belts makes maintenance and repairs a breeze. Individual components can be quickly and easily replaced when worn or damaged, ensuring minimal downtime and reducing the overall cost of ownership.

Minimal Friction and Noise Generation

Plastic Conveyor Belts generate minimal friction and noise during operation, making them an excellent choice for industries that require a quiet and efficient conveyor solution. This feature is particularly valuable in sensitive environments, such as food processing facilities, where noise reduction is crucial for both employees and product quality.

Ideal Industries and Applications for Plastic Conveyor Belts

Food Processing Industry

In the food processing industry, Plastic Conveyor Belts are a popular choice due to their hygienic design and ease of cleaning. These belts are ideal for applications such as processing raw ingredients, conveying packaged goods, or handling delicate products like baked goods or confectioneries.

Materials Handling and Packaging

The adaptability and customisation options of Plastic Conveyor Belts make them an excellent fit for materials handling and packaging applications. They can be easily configured to transport a variety of products, allowing for efficient sorting, packing, and distribution in industries such as pharmaceuticals, consumer goods, and more.

Warehousing and Distribution

In warehousing and distribution facilities, Plastic Conveyor Belts provide an efficient and reliable solution for transporting goods between different areas or zones. Their sturdy construction and modular design allow them to accommodate a wide range of products and weights, ensuring smooth and efficient operations.

Automotive and Manufacturing Industries

Plastic Conveyor Belts are also commonly used in automotive and manufacturing industries, where they can be employed for the transport of various components and assemblies. Their versatility and customisation options ensure that they can cater to the unique requirements of these sectors, promoting streamlined production processes.

Effective Maintenance Practices for Plastic Conveyor Belts

Routine Inspection and Monitoring

Performing regular inspections and monitoring the performance of your Plastic Conveyor Belt is essential to ensuring its optimal operation and longevity. Check for signs of wear or damage, such as worn or broken links, and address these issues promptly to avoid costly downtime and prolong the belt’s service life.

Proper Cleaning and Sanitation

Maintaining a clean and hygienic conveyor system is particularly important in industries with strict cleanliness requirements, such as food processing. Regularly clean your Plastic Conveyor Belt using appropriate cleaning methods for your specific belt material and application, ensuring the removal of debris and product build-up.

Tension and Tracking Adjustments

Maintaining proper tension and tracking in your Plastic Conveyor Belt is crucial to its overall performance and longevity. Follow the manufacturer’s recommendations for tensioning and adjusting tracking, ensuring smooth and efficient operation.

Component Replacement

Over time, components of your Plastic Conveyor Belt may wear and require replacement. By closely monitoring the belt’s condition and its components, and replacing parts as necessary, you can maintain the performance and efficiency of your conveyor system, reducing the risk of unexpected breakdowns and downtime.

Maximise Efficiency with Plastic Conveyor Belts

With their unique features, customisation options, and ease of maintenance, Plastic Conveyor Belts are an excellent choice for a wide range of industries and applications. By understanding the benefits of these belts, implementing them in suitable settings, and adhering to essential maintenance practices, you can optimise your conveyor system’s performance and extend its service life.

Whether you work in food processing, materials handling, packaging, warehousing, automotive manufacturing, or any other industry where efficient and adaptable conveying solutions are critical, incorporating Plastic Conveyor Belts into your conveyor system can help you achieve reliable, effective, and consistent product transportation within your facility.

Invest in the versatility and adaptability of Plastic Conveyor Belts, and watch your conveyor system’s performance soar. Visit the website of Change Parts Pty Ltd for more information.