In the conveyor belt systems arena, many designs and materials are available to cater to the diverse needs of different industries. Among these, the Uniflex Conveyor Belt stands out due to its unique features, making it a favourable choice for various applications. In this ultimate guide, we will explore the world of Uniflex Conveyor Belts, their advantages, applications across different sectors, and best practices to ensure optimal performance and durability.

The Uniflex Conveyor Belt is a specialised wire belt characterised by its close, evenly spaced spiral weave and flat, uniform surface. It is manufactured using high-quality stainless steel, providing exceptional strength, durability, and resistance to wear. The intricately woven structure delivers excellent load distribution, resulting in a highly stable and responsive belt suitable for a wide range of industries and applications.

One of the most notable advantages of the Uniflex Conveyor Belt is its superior versatility. Its flat surface can accommodate various product sizes, shapes, and weights, and its tightly woven design enables precise product positioning when required. The Uniflex Conveyor Belt also boasts high temperature and corrosion resistance, making it suitable for high-heat processing or harsh industrial environments.

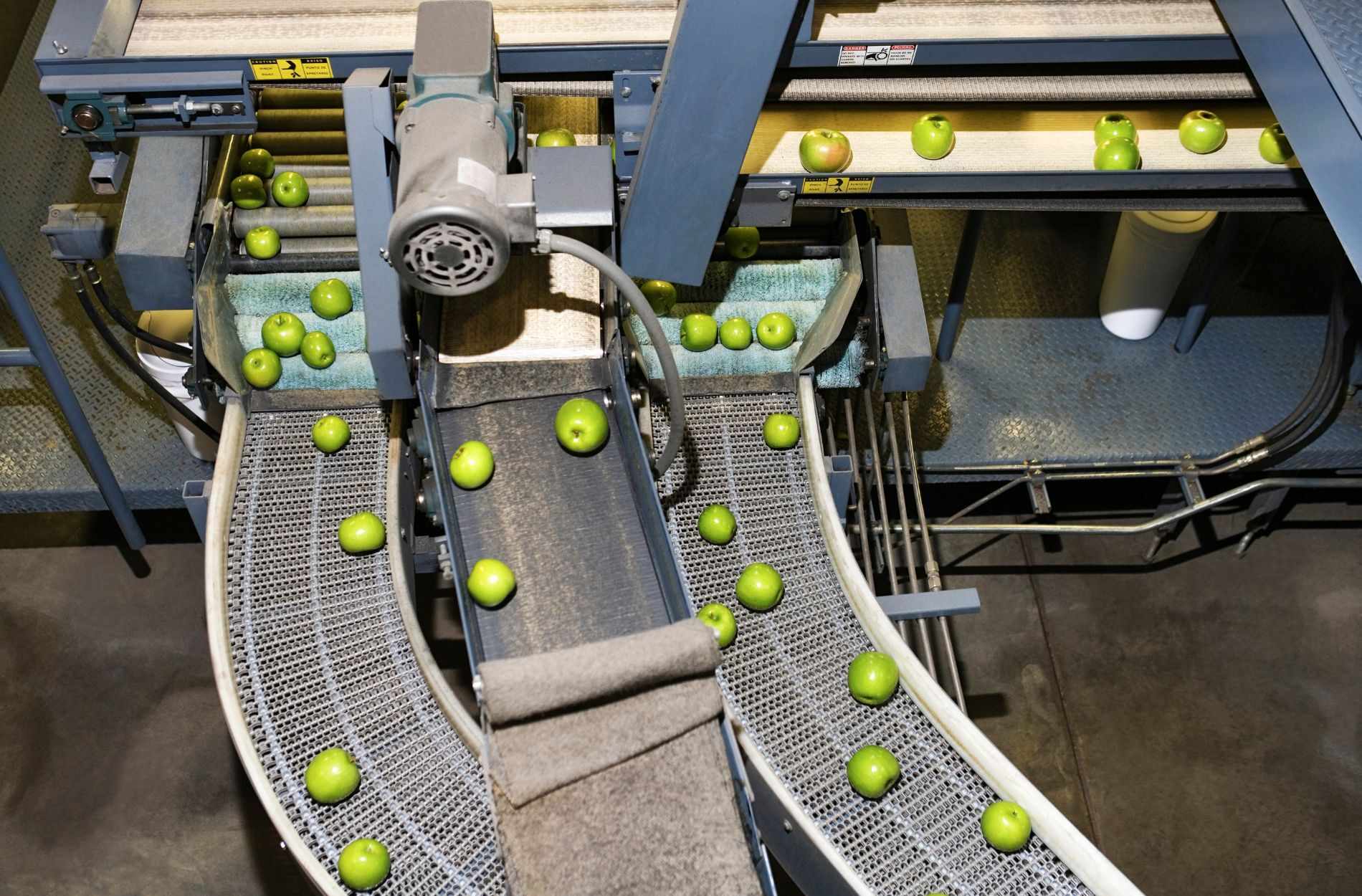

Uniflex Conveyor Belts are commonly used in a variety of industries, including food processing, baking, pharmaceuticals, and general manufacturing. They are particularly popular in applications where a hygienic, hard-wearing, and heat-resistant belt is essential, such as in the production of baked goods, confectionery, or medications.

Maintaining the longevity and optimal functionality of your Uniflex Conveyor Belt is crucial to the efficiency of your conveyor system. Regular inspection and maintenance practices, such as checking for wear, ensuring proper tension and alignment, and cleaning the belt thoroughly, will contribute to reduced downtime and a longer belt lifespan.

Throughout this comprehensive guide, we will delve deeper into the benefits, applications, and maintenance guidelines surrounding Uniflex Conveyor Belts, providing you with the knowledge and tools necessary to elevate the performance of your conveyor system and maximise its efficiency.

Features and Advantages of Uniflex Conveyor Belts

Superior Strength and Durability

Uniflex Conveyor Belts are made from high-quality stainless steel, which provides them with outstanding strength and durability. Their intricately woven design and even load distribution contribute to their hard-wearing nature, allowing them to withstand the rigours of demanding industrial environments while maintaining optimal functionality and longevity.

High Temperature and Corrosion Resistance

The use of stainless steel materials in Uniflex Conveyor Belts offers excellent resistance to high temperatures and corrosion. This makes them suitable for facilities requiring heat-resistant belts, such as baking and food processing plants. Furthermore, their corrosion resistance ensures that they can continue to perform optimally in harsh industrial environments or applications involving corrosive substances.

Versatility and Product Handling

One of the key advantages of Uniflex Conveyor Belts is their versatility in handling products of varying sizes, shapes, and weights. Their flat, uniform surface ensures that even small or delicate items can be transported safely and securely. This adaptability makes them a popular choice for businesses and industries with diverse product handling requirements.

Precise Product Positioning

Uniflex Conveyor Belts have a tightly woven design that allows for precise product positioning during transportation. This feature is crucial in applications where accurate placement of items on the belt is necessary, such as assembly lines or sorting processes.

Applications of Uniflex Conveyor Belts

Food Processing and Baking

Uniflex Conveyor Belts are extensively used in the food processing industry, where they can be found in various applications, from bakery lines to candy production. Their high-temperature resistance makes them well-suited for handling baked goods that need to be transported in and out of ovens, while their corrosion resistance ensures that they can withstand the rigours of a food processing environment.

Pharmaceutical Industry

In the pharmaceutical industry, precise product positioning and the use of hygienic, easy-to-clean conveyor belts are crucial. Uniflex Conveyor Belts cater to these requirements, making them an ideal choice for transporting and processing medications. Their flat surface allows for accurate placement and spacing of pills or capsules, while the stainless steel construction ensures that they are easy to clean and maintain in accordance with stringent industry guidelines.

General Manufacturing and Assembly Lines

Uniflex Conveyor Belts’ high strength, durability, and ability to handle products of varying sizes make them a popular choice in general manufacturing and assembly line applications. By providing accurate product positioning and seamless transportation, these belts contribute to efficient and streamlined production processes.

Maintaining Your Uniflex Conveyor Belt

Regular Inspection

To ensure that your Uniflex Conveyor Belt continues to operate at peak efficiency, it is important to conduct regular inspections. Look for signs of wear or damage, such as frayed edges, broken spirals, or loose weaves. Addressing any issues promptly can help prevent costly downtime and extend the overall lifespan of the belt.

Proper Tension and Alignment

Maintaining the proper tension and alignment of your Uniflex Conveyor Belt is crucial to its optimal performance and longevity. Incorrect tension can lead to uneven wear, tracking issues, or even belt slippage. Ensure that you follow the manufacturer’s recommendations for tensioning to prevent unnecessary wear and tear.

Cleaning and Sanitation

Hygiene and cleanliness are vital concerns in industries such as food processing and pharmaceuticals. To maintain a clean and sanitary conveyor system, it is essential to regularly clean your Uniflex Conveyor Belt. Use a mild detergent and warm water, or an industry-approved cleaner and sanitiser to prevent the buildup of dirt, grease, or other contaminants that can affect product quality and belt performance.

Lubrication

While Uniflex Conveyor Belts are generally low maintenance, periodic lubrication of the belt’s moving parts may be required, depending on their specific application and working environment. Follow the manufacturer’s guidelines for lubrication intervals and lubricant type to ensure that your belt continues to run efficiently and smoothly.

Maximise the Efficiency of Your Uniflex Conveyor System

The Uniflex Conveyor Belt offers numerous benefits and advantages, making it an ideal choice for a wide range of industries and applications. By understanding its unique features, common applications, and best practices for maintenance, you can ensure the optimal performance and longevity of your conveyor system.

Investing in the right type of conveyor belt and committing to proper upkeep will result in a more efficient and effective system, ultimately contributing to the overall success of your business operations. Visit the website of Change Parts Pty Ltd for more information.