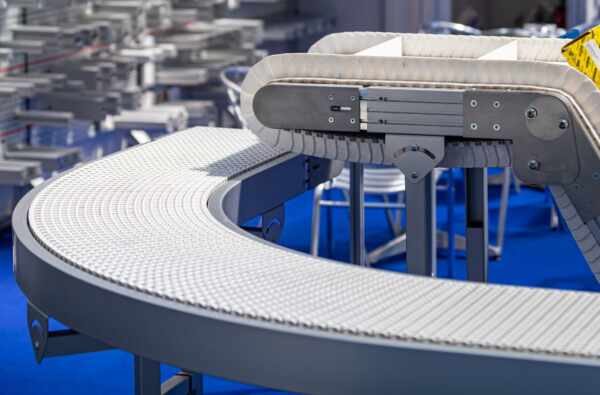

The food manufacturing industry depends on efficient and reliable conveyor systems to keep production flowing smoothly. Conveyor belts are an essential component, ensuring that ingredients and finished products get where they need to go while maintaining quality and safety standards.

With a wide variety of conveyor belt options available on the market, it’s essential to understand the benefits and limitations of each type before making a decision for your food manufacturing facility. In this comprehensive guide, we will explore the different types of conveyor belts suitable for food manufacturing and help you determine which one is the best fit for your specific needs.

First and foremost, it’s crucial to consider the safety standards and hygiene requirements in the food manufacturing industry. Conveyor belts must be designed to meet these high standards, ensuring that food products can be safely prepared, processed, and packaged. Numerous factors come into play when selecting a conveyor belt, such as the type of food being produced, the belt material, and the overall manufacturing process.

One popular type of conveyor belt used in the food industry is the steel belt. Steel belts offer several advantages, such as high strength, durability, and resistance to cutting or tearing. Additionally, they are easy to clean and maintain, making them an excellent choice for environments where sanitation is of utmost importance. In particular, steel belts are well-suited for baking, freezing, and other high-temperature processes.

Another common choice for food manufacturing conveyor belts is the modular belt. These belts consist of interlocking plastic modules, which allow for easy customisation and adjustment to fit specific requirements. Modular belts are particularly effective in applications where frequent belt replacement or repair is necessary, as individual modules can be replaced without needing to replace the entire conveyor belt.

As you continue reading this guide, we will delve deeper into the benefits, applications, and factors to consider when selecting the right conveyor belt for your food manufacturing facility. Additionally, we will discuss how to determine when it’s time to replace or repair your conveyor belt, ensuring that your production line remains efficient and reliable at all times. So, let’s get started on the journey to finding the perfect conveyor belt solution for your unique needs!

A Comprehensive Guide to Choosing the Right Conveyor Belt for Your Food Manufacturing Facilities

Understanding the Different Types of Conveyor Belts

When selecting a conveyor belt for your food manufacturing facility, it’s essential to understand the various types available and their unique characteristics. The following are some common types of conveyor belts used in the food industry:

1. Steel belts: Made from stainless steel, these belts are known for their high strength, durability, and resistance to cutting or tearing. Steel belts are also easy to clean and maintain, making them an ideal choice for food applications where hygiene is critical. Their high-temperature resistance makes them suitable for use in baking, freezing, and other heat-related processes.

2. Modular belts: These belts consist of interlocking plastic modules, which can be easily customised and adjusted to fit various requirements. Modular belts are an excellent option for applications requiring frequent belt replacement or repair since individual modules can be replaced without having to replace the entire conveyor belt. They also offer a high level of hygiene due to their ease of cleaning.

3. Fabric belts: Made from multiple layers of fabric, these conveyor belts are flexible and lightweight. They are often used in food processing applications where lightweight and gentle handling of products is crucial. Fabric belts are suitable for use in the baking and confectionery industries but may not be ideal for high-temperature or high-stress applications.

4. Positive drive belts: These belts use a sprocket-driven system, ensuring accurate product positioning without slipping. With their easy-to-clean design, positive drive belts are an excellent option for food manufacturing processes that require precise product handling and minimal maintenance.

Evaluating Your Food Manufacturing Process Requirements

When selecting the right conveyor belt for your food manufacturing facility, it’s imperative to assess your specific needs and requirements. Consider the following factors:

1. Product characteristics: The type, size, and weight of food products being manufactured will impact the choice of conveyor belt. Heavier or bulkier products may require a more robust belt like steel, while lighter products might work better with fabric or modular belts. Similarly, abrasive or sharp products may require belts with higher cut resistance.

2. Temperature conditions: Different conveyor belts have varying temperature resistance properties. Steel belts are ideal for high-temperature applications, while fabric belts are better suited for low-temperature or room temperature processes. Modular belts offer a reasonable temperature range but may not be suitable for extreme temperatures.

3. Moisture and humidity: Wet or moist environments can cause challenges in handling food products and can lead to hygiene concerns. Modular and positive drive belts are often the best options for these conditions due to their easy cleaning and reduced risk of harbouring bacteria.

4. Cleaning and sanitation requirements: Food safety regulations require conveyor belts to be cleaned and sanitised regularly. Steel and modular belts are easy to clean and maintain, making them more suitable for food manufacturing processes that require high hygiene standards.

5. Line speed and efficiency: Conveyor belt efficiency and reliability are crucial in maintaining production line speed and minimising downtime. Modular and positive drive belts offer precise product handling and positioning, making them ideal for high-speed production lines.

Maximising Conveyor Belt Lifespan and Reliability

To ensure the longevity and reliability of your conveyor belt, it’s important to regularly inspect and maintain it. Look for signs of wear, damage, or contamination, and address any issues promptly to prevent the need for costly belt replacement or repairs. Consider the following maintenance tips:

1. Regular inspections: Schedule routine conveyor belt inspections to identify and rectify potential issues early. This can help extend the belt’s lifespan and maintain optimal performance.

2. Cleaning and sanitation: Regular cleaning and sanitation of the conveyor belt are crucial for maintaining hygiene standards and preventing product contamination in food manufacturing facilities. Make sure to follow the manufacturer’s recommendations for proper cleaning and sanitation procedures.

3. Proper tension and tracking: Conveyor belts should be tensioned and tracked correctly to ensure smooth operation and reduce the risk of belt slip, misalignment, or damage. Check the manufacturer’s guidelines for the correct tension and tracking adjustments.

4. Lubrication: Some conveyor belts may require lubrication to maintain optimal performance and prevent wear. Follow the manufacturer’s recommendations for the appropriate lubrication type and frequency.

Conclusion

Selecting the right conveyor belt for your food manufacturing facility is a critical decision that influences your production line’s performance, efficiency, and safety. By carefully considering the various types of conveyor belts, evaluating your specific process requirements, and implementing a proper maintenance plan, you can ensure that your conveyor belt system is a valuable asset in your food manufacturing operation.

Still unsure which conveyor belt is right for your food manufacturing facility? The expert team at Change Parts Pty Ltd is here to help. Get in touch with us today to discuss your unique requirements and find the perfect conveyor belt solution.