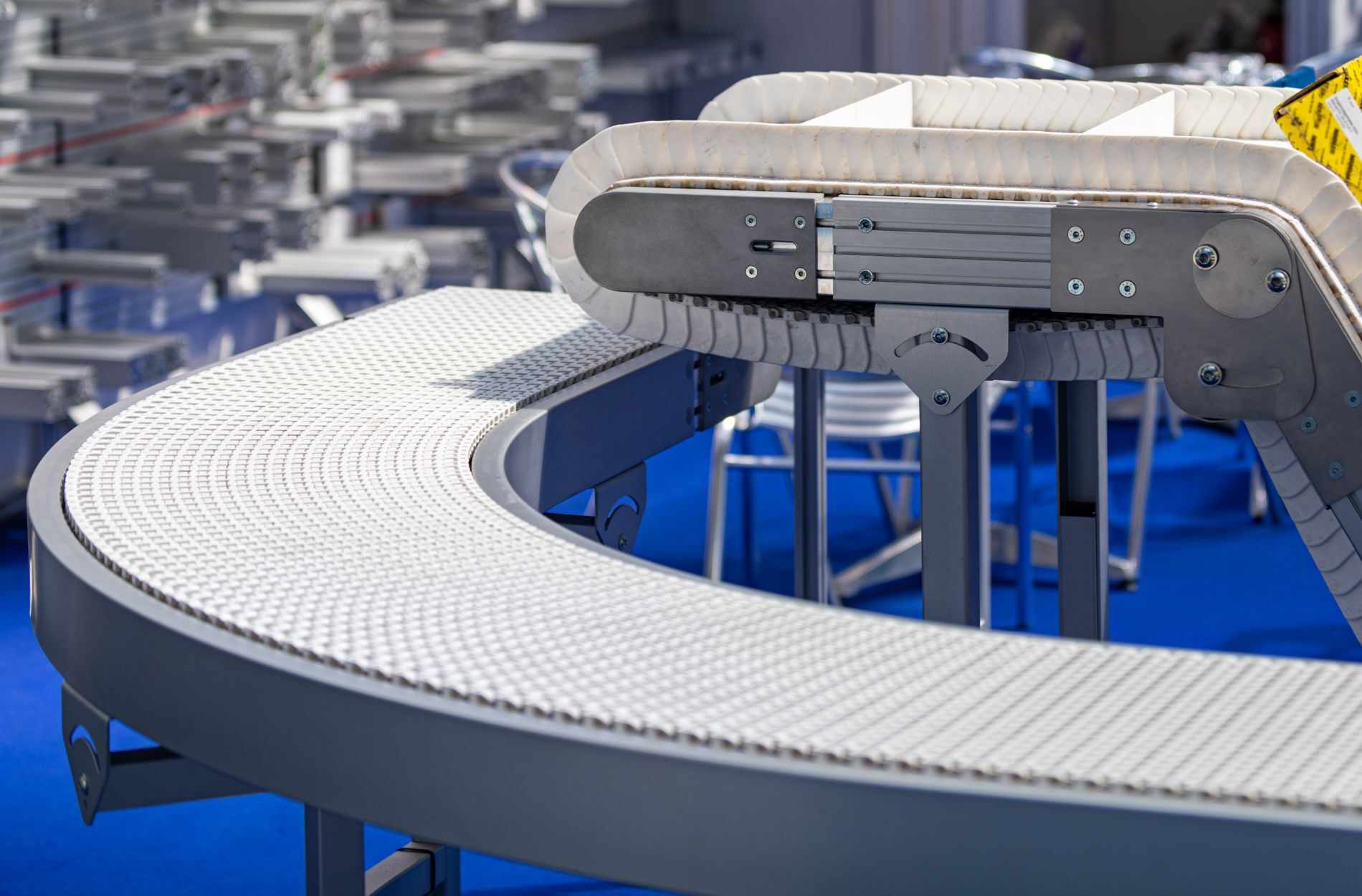

Modular conveyor belts have become increasingly popular in various industries due to their ability to adapt to a wide array of applications whilst offering superior performance, ease of maintenance, and sustainability. These belts consist of interlocking plastic modules, which can be easily configured and replaced to suit your specific conveyor requirements, making them an excellent choice for businesses looking to boost efficiency and streamline their manufacturing processes.

As industries continue to evolve and adapt in 2024, the need for flexible and reliable conveyor systems has never been greater. Modular conveyor belts provide businesses with the ability to quickly adapt their conveying solutions to match changing production needs and accommodate varying product lines, all without compromising on performance or efficiency. In this blog, we will delve into the world of modular conveyor belts, examining their applications, benefits, and how you can maximise their potential in your operation.

We will explore the key factors to consider when selecting a modular conveyor belt system, including your specific industry and product requirements, the desired level of customisation and versatility, and your maintenance preferences. Moreover, we will provide recommendations on how to optimise your modular conveyor belt, ensuring it operates at maximum efficiency throughout its lifespan.

Understanding Modular Conveyor Belts: Applications, Benefits, and Tips for Maximising Efficiency in Various Industries

1. Applications of Modular Conveyor Belts Across Industries

Modular conveyor belts have gained popularity due to their flexibility and adaptability in a wide range of industrial applications. Some of the key industries that benefit from modular conveyor belts include:

– Food and beverage processing: With their hygienic properties and easy cleaning, modular belts are ideal for handling products such as packaged goods, raw ingredients, and even delicate items like bakery and confectionery products.

– Pharmaceutical and medical manufacturing: The ease of customisation and meticulous precision provided by modular belts make them suitable for transporting sensitive medical components and ensuring compliance with stringent manufacturing regulations.

– Packaging and material handling: Modular conveyor belts excel in transporting and sorting diverse packages and shapes, ensuring efficient product handling and maximising overall productivity.

– Assembly lines and automotive manufacturing: The customisability and durability of modular belts make them capable of handling various components and materials, contributing to a seamless assembly process and streamlined automotive production.

2. Benefits of Using Modular Conveyor Belts

Modular conveyor belts offer a wide array of advantages over traditional conveyor systems, including:

– Versatility: With their interlocking modules, modular conveyor belts can be easily configured to suit any specific application or layout, catering to the changing needs of businesses in today’s fast-paced manufacturing landscape.

– Hygiene and safety: The non-absorbent properties and ease of cleaning associated with modular belts make them an ideal choice for industries requiring strict adherence to food safety and hygiene standards.

– Ease of maintenance and repair: Modular conveyor belts enable individual modules to be easily swapped or replaced, resulting in minimal downtime and reduced maintenance costs.

– Enhanced durability: Constructed from high-quality materials, modular conveyor belts provide exceptional resilience and long-lasting performance, ensuring your operation remains productive and efficient.

3. Tips for Maximising Efficiency with Your Modular Conveyor Belt System

To ensure you get the most out of your modular conveyor belt system, consider the following efficiency-boosting tips:

– Customise your belt configuration: Assess your specific application requirements and configure your modular belt to achieve optimal compatibility, resulting in higher efficiency and a longer service life.

– Regular inspection and maintenance: Conduct routine checks to identify and address potential issues, such as damaged modules or debris buildup, to ensure your belt operates at peak efficiency.

– Appropriate belt material selection: Consider factors like product weight, environmental conditions, and industry requirements when choosing the ideal belt material to ensure lasting performance and minimal downtime.

– Proper tensioning and alignment: Sufficient tension and alignment are essential in preventing excess wear and tear, ensuring smooth operation, and extending the lifespan of your modular conveyor system.

4. Choosing the Right Modular Conveyor Belt for Your Operation

With various modular conveyor belt options available, it’s essential to select the right belt that best aligns with your specific industry requirements and application needs. Key factors to consider include:

– Material compatibility: Ensure the belt material is suitable for your intended application, taking into account factors such as product weight, chemical compatibility, and temperature requirements.

– Belt design and configuration: Select a modular belt design that aligns with your conveying needs, considering factors like product size, shape, and desired throughput.

– Customisation and versatility: Choose a modular belt system that offers the level of customisation necessary for your operation, ensuring optimal efficiency and adaptability for future business growth.

– Maintenance and repair preferences: Opt for a modular conveyor belt that meets your maintenance and repair preferences, balancing ease of access, replacement costs, and overall system reliability.

Conclusion

Modular conveyor belts offer a highly adaptable and versatile solution for businesses looking to optimise their manufacturing processes and better accommodate changing industry needs. With their numerous benefits, including ease of maintenance, enhanced durability, and customisability, modular conveyor belts provide an excellent choice for various applications across a wide array of industries.

If you’re looking to enhance your operation with a modular conveyor belt system, reach out to our team of experts at Change Parts Pty Ltd for guidance and support. We’re committed to helping you navigate the world of conveyor systems and finding the perfect solution to ensure your operation remains efficient, productive, and prepared for the challenges of 2024 and beyond.