Steel conveyor belts are an innovative solution for businesses needing reliable, durable, and efficient material handling equipment. These belts are designed to withstand harsh environments and heavy workloads, making them ideal for various industries such as food manufacturing, mining, recycling, and more. With their robust construction and capability to support a wide range of products, steel conveyor belts can be a game changer in improving your manufacturing processes while reducing downtime and maintenance costs.

As the demand for efficient and reliable conveying solutions increases in 2024 and beyond, businesses need to stay ahead of the curve by choosing the right equipment to streamline their operations. In this blog post, we will delve into the applications and benefits of steel conveyor belts, exploring their advantages over other belt types and providing guidance on selecting the best option to suit your industry and production requirements.

We will discuss the various types of steel conveyor belts available on the market, offering an overview of their structure, characteristics, and suitability for different applications. Furthermore, we will provide insights on how to maintain and extend the lifespan of your steel conveyor belt, ensuring optimal performance and long-term return on investment.

Steel Conveyor Belts: Applications, Benefits, and Choosing the Right Type for Your Manufacturing Needs

1. Applications of Steel Conveyor Belts in Various Industries

Steel conveyor belts have been widely adopted across numerous industries thanks to their unique characteristics and unmatched durability. Here are some of the most common applications of steel belts:

– Food manufacturing: Steel belts are often the go-to choice for food processing facilities due to their hygienic properties, ease of cleaning, and resistance to high temperatures and moisture. From baking to freezing processes, steel conveyor belts play a critical role in streamlining food production.

– Mining and heavy-duty material handling: The strength and durability of steel make these belts ideal for transporting heavy and abrasive materials in mining, quarrying, and bulk handling operations.

– Recycling and waste management: Steel conveyor belts can handle and separate a variety of waste materials, including plastics, metal, paper, and more, making them essential for efficient recycling processes.

– Assembly lines and manufacturing plants: In manufacturing settings, steel belts provide the necessary stability and precision to convey even the most delicate components, ensuring seamless production processes.

2. Advantages of Steel Conveyor Belts Over Other Belt Types

There are several reasons why steel conveyor belts have become increasingly popular in various industries:

– Durability: Steel belts are known for their exceptional strength and resistance to damage, ensuring reliable performance in even the most demanding applications.

– High load capacity: The robust construction of steel conveyor belts allows them to carry heavy loads easily, making them an ideal choice for industries handling bulky products and materials.

– Increased efficiency: Steel belts can run at high speeds, streamlining production processes and improving overall operational efficiency in your manufacturing facilities.

– Hygienic properties: With their non-absorbent, easy-to-clean properties, steel belts are perfect for industries requiring strict hygiene standards, such as food manufacturing.

– Long lifespan: The lasting durability and minimal maintenance requirements of steel conveyor belts result in longer service life and significant savings on maintenance costs over time.

3. Choosing the Right Type of Steel Conveyor Belt for Your Needs

With several types of steel conveyor belts available on the market, it’s essential to select the best option tailored to your specific industry and application requirements. Here are some common steel belt types and their characteristics:

– Flat wire belts: Featuring a mesh-like structure of flat steel wires, these belts are ideal for transporting light to medium-weight products, ensuring good ventilation and drainage for perishable items.

– Chain-driven metal belts: Combining a sturdy chain with a steel mesh belt, these belts are perfect for applications that require stable and precise product positioning, such as assembly lines or high-speed conveying.

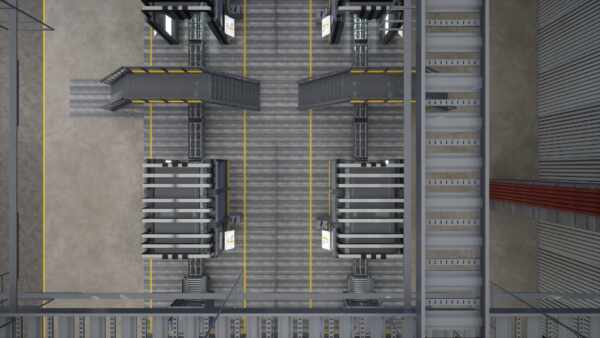

– Hinged steel belt conveyor: These heavy-duty belts are designed to handle bulky and abrasive materials, with interlocking steel plates allowing them to handle a wide range of products and applications.

– Wire mesh conveyor belts: Featuring woven wire mesh, these belts offer excellent ventilation and drainage properties, making them suitable for food processing and other applications that require airflow and temperature control.

4. Maintaining and Extending the Lifespan of Your Steel Conveyor Belt

Proper maintenance is key to ensuring the longevity and optimal performance of your steel conveyor belt. Here are some maintenance tips to extend your belt’s lifespan:

– Regular inspections: Schedule routine checks to identify signs of wear and tear, such as broken or misaligned links, rust, or damaged edges, and address any issues promptly.

– Lubrication: Apply lubrication to your belt’s chains and components as needed, ensuring frictionless movement and reduced wear.

– Cleaning: Clean your steel conveyor belt regularly to remove any debris or residue, promote hygiene, and prevent premature wear or equipment failure.

– Adjust tension: Ensure that your belt tension is adjusted appropriately to prevent overstraining or sagging, which can lead to damage and negatively impact conveying efficiency.

Conclusion

Steel conveyor belts are a versatile and durable solution for a wide range of industries and applications. By understanding the advantages, applications, and different types of steel belts, you can make an informed decision on choosing the right conveyor belt to enhance the efficiency, reliability, and productivity of your manufacturing operations.

For expert advice on selecting, maintaining, and optimising your steel conveyor belt system, don’t hesitate to reach out to our team at Change Parts Pty Ltd. We’re here to help you get the most out of your conveyor belt solutions, ensure success and growth in 2024 and beyond.