In the food manufacturing industry, maintaining high standards of cleanliness and hygiene is not only essential for ensuring product quality and safety but also a legal requirement. A critical element of your facility’s hygiene management involves properly cleaning and maintaining conveyor belt systems, which are responsible for efficiently transporting food products during production. Failure to uphold these standards can result in product contamination, potential accidents, and costly downtime.

It’s vital to establish a comprehensive conveyor belt cleaning strategy tailored to your facility’s unique needs to maintain optimal hygiene levels and enhance operational efficiency. By incorporating periodic cleaning schedules, choosing the appropriate cleaning methods and equipment, and upholding consistent sanitation standards in your daily operations, you can ensure that your food manufacturing facility remains a clean, safe, and efficient environment.

In this detailed guide, we will explore best practices and expert tips for cleaning conveyor belts in food manufacturing facilities, offering insights on various cleaning methods, critical cleaning factors, and how to implement a robust sanitation plan. Learn how to maintain the cleanliness and performance of your conveyor belt systems, paving the way for operational efficiency, enhanced productivity, and the long-term success of your food manufacturing facility.

Establishing a Cleaning Schedule

Implementing a regular cleaning schedule is the first step towards maintaining optimal cleanliness and hygiene standards for your conveyor belt systems. Consider the following factors when developing your cleaning plan:

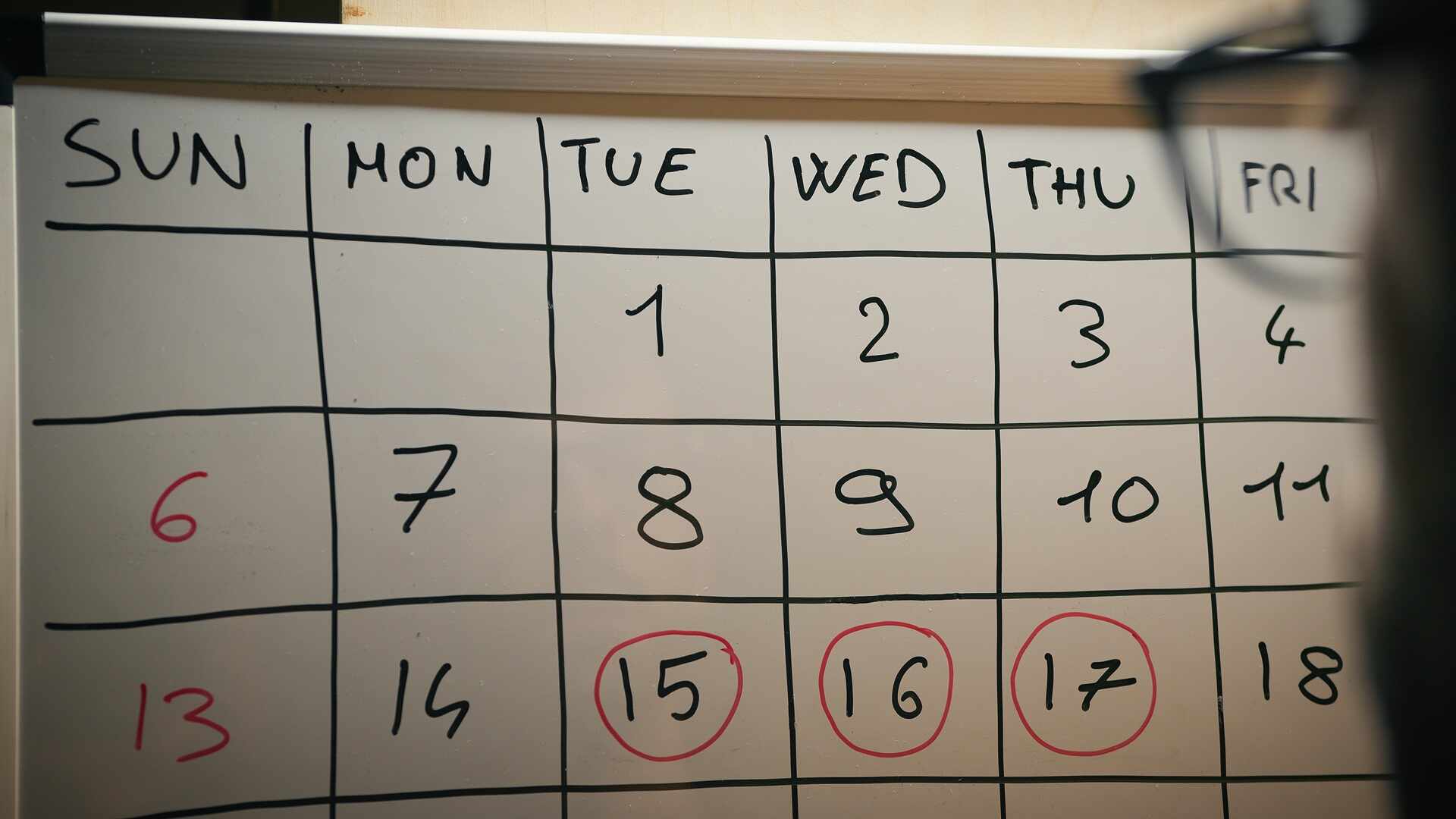

1. Frequency of Cleaning: Depending on your facility’s production volume, nature of food products, and degree of contamination risk, determine the appropriate cleaning frequency. Daily or weekly cleaning may suffice in some cases, while other facilities may require multiple daily cleaning sessions.

2. Cleaning Shifts: Strategically schedule cleaning tasks during planned production breaks or shift changes to minimise operational downtime and maintain productivity levels.

3. Monitoring and Inspection: Incorporate regular conveyor belt system inspections into your cleaning schedule, checking for signs of wear, damage, and potential contaminants. Promptly address any issues discovered during inspections to prevent further contamination or risk of system failure.

Selecting the Right Cleaning Methods and Equipment

To effectively clean and maintain your conveyor belt systems, choose the appropriate cleaning methods and equipment based on belt type, facility environment, and handling of food products. Common cleaning techniques include:

1. Manual Cleaning: This method involves physically scrubbing the conveyor belts with brushes, sponges, and cleaning solutions. Manual cleaning is time-consuming but can be effective for small-scale operations or as a supplementary cleaning step. Ensure workers handling this task are adequately trained and follow strict safety precautions.

2. Foaming Systems: Foaming systems utilise high-pressure nozzles or foam generators to spray cleaning solutions and foam onto conveyor belts. The foam clings to the conveyor surfaces, providing an extended contact time for the cleaning agents to dissolve and remove contaminants. These systems suit various conveyor belt types and can efficiently clean large surface areas with minimal downtime.

3. Clean-in-Place (CIP) Systems: CIP systems are automated cleaning solutions integrated into conveyor belt systems, allowing continuous cleaning throughout production. Conveyor belts pass through cleaning stations, which spray, scrub, and rinse the belt surfaces, removing contaminants and ensuring consistent cleanliness. CIP systems are especially useful for facilities with strict hygiene requirements and high production volumes.

4. Ultrasonic Cleaning: Ultrasonic cleaning utilises high-frequency sound waves to create cavitation bubbles in cleaning solution, generating intense pressure and removing contaminants from conveyor belt surfaces. This method is highly effective for intricate system components or hard-to-reach areas and requires minimal manual intervention.

Critical Cleaning Factors to Consider

To maximise the effectiveness of your conveyor belt cleaning strategy, consider the following critical factors:

1. Compatibility: Choose cleaning methods and solutions compatible with your conveyor belt materials and components, ensuring that cleaning processes do not damage the belt or affect its overall integrity.

2. Concentration and Temperature: Properly regulate the concentration of cleaning solutions and water temperature to achieve maximum cleaning effectiveness without causing damage to conveyor system components.

3. Rinsing: Thorough rinsing is essential to remove residues from the cleaning agents after cleaning. Prioritise efficient and complete rinsing to prevent potential contamination and residue build-up.

4. Sanitisation: Sanitise conveyor belt surfaces after cleaning to kill pathogens and ensure comprehensive hygiene management. Opt for suitable food-grade sanitisers that comply with relevant industry standards and regulations.

Maintaining Consistent Sanitation Standards

Implementing a robust conveyor belt cleaning plan is just the beginning when it comes to maintaining high levels of hygiene and cleanliness in your food manufacturing facility. To ensure long-term success, establish consistent sanitation standards and practices throughout your operations:

1. Training: Provide regular training programs for your employees on proper cleaning and sanitation procedures, ensuring they understand their role in maintaining a clean and efficient food manufacturing facility.

2. Documentation: Develop and maintain comprehensive documentation for all cleaning procedures, equipment, and schedules, enabling you to track and revise your sanitation processes as needed.

3. Audits and Compliance: Regularly conduct internal audits to assess your cleaning practices’ effectiveness and identify improvement areas. Comply with relevant regulations and industry standards to ensure the safety and quality of your food products.

Conclusion

Maintaining high hygiene standards while maximising efficiency in your food manufacturing facility is essential for product quality, safety, and competitive advantage. By developing a comprehensive conveyor belt cleaning strategy and applying best practices, you can keep your operations in top shape, ensuring long-term success and sustained customer trust.

Ready to optimise your food manufacturing facility’s conveyor belt cleaning and maintenance processes? Contact Change Parts Pty Ltd today for expert guidance, industry-leading conveyor belt equipment, and unrivalled support to help you navigate the complexities of hygiene management and boost your facility’s performance.