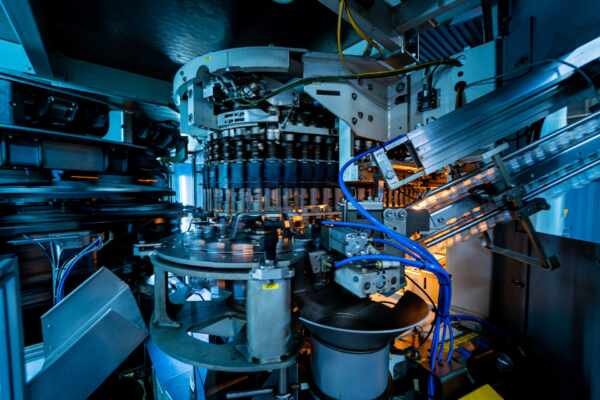

Regular conveyor belt maintenance is integral to maintaining efficiency, safety, and hygiene in food manufacturing operations. Conveyor belt systems play a pivotal role in transporting raw materials, moving products through various stages of the production process, and facilitating packaging. A well-maintained conveyor belt system not only ensures the smooth functioning of your operation but also upholds food safety standards and minimises costly downtime. Neglecting maintenance can lead to conveyor belt disruptions, substandard product quality, and potential safety hazards, threatening the success and profitability of your food manufacturing operation.

In this article, we will examine the importance of regular conveyor belt maintenance in food manufacturing and explore best practices for keeping conveyor belts in optimal working order. Learn how to effectively maintain your conveyor belt system, identify signs that indicate the need for repair or replacement, and discover how to extend the life of your conveyor belts through timely and diligent maintenance. With the proper care and attention, you can ensure the smooth and uninterrupted operation of your food manufacturing processes while abiding by industry standards.

Defining a Conveyor Belt Maintenance Plan

A comprehensive conveyor belt maintenance plan involves periodic inspection, cleaning, and adjustments to ensure optimal performance. To achieve effective maintenance, consider implementing the following:

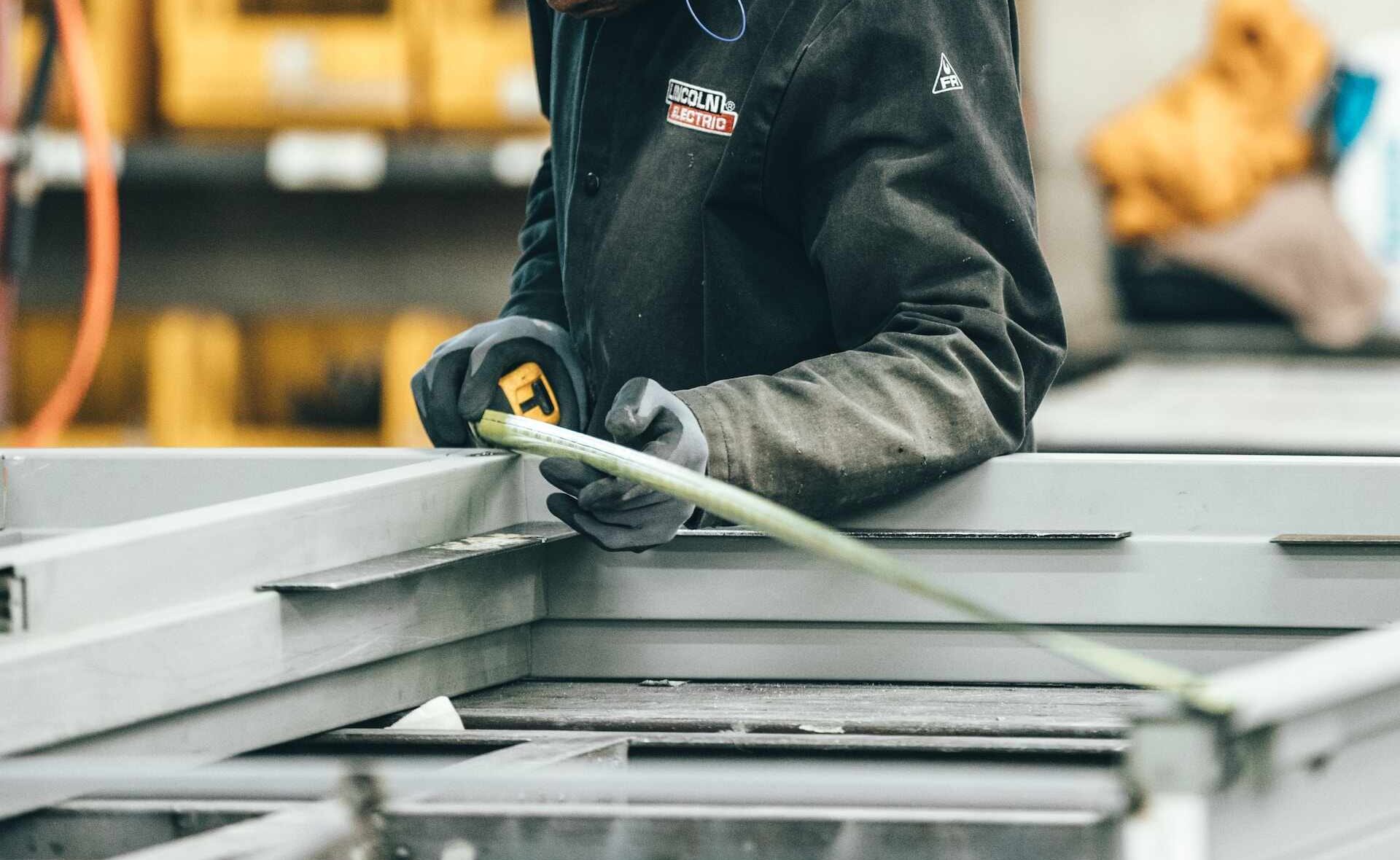

1. Scheduled Inspections: Establish regular inspection intervals to identify potential issues early on. Examine wear patterns, belt tension, drive components, and other critical parts for signs of distress or malfunction. Regular inspections can help prevent unscheduled downtime and costly repairs.

2. Cleaning Procedures: Implement a strict cleaning protocol, especially for food-grade conveyor belts. Utilise appropriate cleaning tools and chemicals to remove food debris, oil, and dust and adhere to food safety standards.

3. Adjustments and Repairs: As needed, adjust the belt tension, tracking, and drive components to maintain optimal system performance. Address minor repairs swiftly to prevent them from escalating into more significant problems.

4. Record Keeping and Reporting: Maintain detailed records of conveyor belt maintenance, inspections, adjustments, and repairs. This documentation enables you to track the conveyor belt’s history, prolong its lifespan, and streamline future maintenance activities.

Identifying Signs of Conveyor Belt Wear and Damage

To effectively extend your conveyor belt system’s life and maintain operational efficiency, it’s crucial to detect early warning signs of wear or damage. Common indicators include:

1. Belt Fraying: Examine the belt edges for fraying or obvious wear. Frayed belts can affect proper tracking and may potentially contaminate food products.

2. Vibration and Noise: Excessive noise or vibration during operation can signal misalignments or damaged components, which should be addressed immediately.

3. Tracking Issues: Watch for the belt moving from side to side, indicating tracking issues or uneven belt wear. Improper tracking can lead to increased wear and, ultimately, belt failure.

4. Damaged Components: Inspect the conveyor belt’s components, including rollers, idlers, drives, and pulleys, for signs of wear or damage. Damaged components can impact the belt’s performance and lead to premature belt failure.

Effective Conveyor Belt Cleaning for Food Manufacturing

Maintaining cleanliness is essential for food-grade conveyor belts to ensure food safety and prevent cross-contamination. Implement the following cleaning best practices:

1. Choose Appropriate Cleaning Techniques: Select cleaning methods that suit your conveyor belt type and food manufacturing process. Options may include dry brushing, wet cleaning, foam cleaning, and using Clean-In-Place (CIP) systems.

2. Use Food-Grade Cleaning Agents: Employ food-grade cleaning chemicals to mitigate the risk of product contamination.

3. Follow Manufacturer Recommendations: Strictly adhere to the conveyor belt manufacturer’s cleaning guidelines to avoid damaging the belt or its components with improper cleaning techniques or chemicals.

4. Train Employees: Ensure your staff are well-trained in the proper conveyor belt cleaning procedures, guaranteeing compliance with food safety standards and maintaining the system’s integrity.

Enhancing Conveyor Belt Life Through Proactive Maintenance

By adopting a strategic approach to conveyor belt maintenance, you can prolong the belt’s life, enhance system efficiency, and uphold your operation’s commitment to food safety. Consider the following proactive maintenance tips:

1. Conduct Regular Equipment Audits: Examine the entire conveyor system, identifying potential wear points and making timely repairs or adjustments. Equipment audits can help resolve minor issues before they escalate into more significant problems.

2. Schedule Preventative Maintenance: Invest in consistent preventative maintenance services, such as belt tracking adjustments or component lubrication, to mitigate operational disruptions and maintain system performance.

3. Implement a Spare Parts Inventory: Keep an inventory of critical spare parts for your conveyor belt system on hand, ensuring swift replacements when needed. This approach minimises downtime and limits disruption to your food manufacturing process.

4. Partner with Professionals: Collaborate with an experienced conveyor belt service provider to ensure optimal maintenance and support tailored to your operation’s unique requirements.

Conclusion

Regular conveyor belt maintenance in food manufacturing operations is crucial for safeguarding efficiency, safety, and hygiene standards. By implementing a comprehensive maintenance plan, proactively identifying signs of wear or damage, and upholding a stringent cleaning regimen, you can maximise your conveyor belt system’s lifespan and performance. Collaborate with industry professionals for expert guidance that caters to your operation’s specific needs, further enhancing conveyor belt upkeep, food safety, and overall efficiency.

Elevate your food manufacturing operation’s conveyor belt maintenance practices with Change Parts Pty Ltd’s professional advice and services. Our experienced team will guide you through, ensuring the longevity, efficiency, and safety of your conveyor belt system.