Conveyor belt systems are integral to the successful operation of countless manufacturing and processing facilities. Ensuring the regular maintenance and proper upkeep of these systems is crucial in maximising their efficiency, reliability, and longevity. Conveyor belt maintenance involves regular inspection, cleaning, and timely repair of any wear or damage that may arise through daily operations, ultimately reducing downtime, increasing productivity, and promoting a safer working environment.

In this informative guide, we will discuss essential conveyor belt maintenance tips and best practices to help you keep your conveyor belt system running smoothly and efficiently. Additionally, we will delve into the importance of conducting regular inspections and address the advantages of partnering with conveyor belt specialists like Change Parts, who can provide expert advice and tailored maintenance solutions to support your facility in maintaining optimal conveyor belt performance.

Conveyor Belt Maintenance: Tips, Best Practices, and Regular Inspection

Establishing a Preventative Maintenance Program

A proactive approach to conveyor belt maintenance enables your facility to detect and address potential issues before they escalate into larger problems. Establishing an effective preventative maintenance program involves the following practices:

1. Develop a maintenance schedule: Create a systematic schedule for inspecting, cleaning, and servicing your conveyor belt system. An ideal schedule will consider factors such as the belt’s type, load capacity, and environmental conditions.

2. Train employees: Properly train all employees involved in maintaining and operating the conveyor belt system. Ensure they understand the maintenance program and are familiar with the various inspection techniques, cleaning procedures, and necessary repairs.

3. Label components and note replacements: Clearly label all conveyor belt components and maintain a log of when they were replaced or repaired. This will help to identify patterns in wear or malfunction and inform decisions regarding component upgrades or replacement.

4. Monitor trends and performance: Constantly evaluate performance trends and recurring maintenance issues to optimise your preventative maintenance program.

Essential Conveyor Belt Inspection Techniques

Regular inspection and evaluation of your conveyor belt system enable you to identify wear and damage at an early stage, mitigating potential downtime and prolonging the belt’s lifespan. Here are some crucial inspection techniques to consider:

1. Visual inspections: Perform regular visual inspections of your conveyor belt system, checking for any signs of wear, damage or misalignment. Identify issues such as frayed edges, damaged rollers, faulty splices, or unusual belt behaviour.

2. Auditory inspections: Listen carefully for any unusual sounds or vibrations during operation, which may indicate a problem with the conveyor belt or one of its components.

3. Component checks: Inspect specific conveyor belt components, such as pulleys, idlers, rollers, and splices, for signs of wear, corrosion, or improper tension.

Cleaning and Lubrication Best Practices

Keeping your conveyor belt clean and well lubricated is essential for optimal performance, reduced wear, and minimized risk of damage. Implement the following best practices:

1. Regular cleaning: Establish a cleaning schedule based on the type and frequency of system usage. Maintain a clean conveyor belt surface by removing contaminants such as dust, dirt, or product residue.

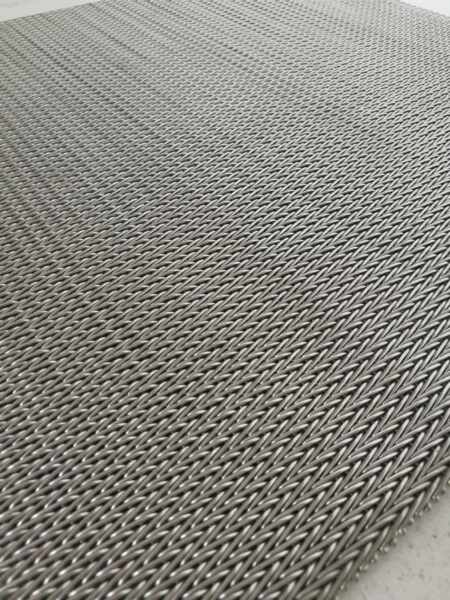

2. Appropriate cleaning methods: Choose suitable cleaning methods and equipment based on your belt’s type and material. For instance, using brushes and vacuum systems for textile belts, or high-pressure water jet systems for steel belts.

3. Lubrication: Regularly lubricate components, such as bearings, gears, and chain drives, according to the manufacturer’s guidelines. Proper lubrication helps prevent premature wear, prolongs component life, and reduces the risk of sudden failure.

Addressing Belt Wear and Damage

Timely identification and repair of belt wear and damage can significantly impact your conveyor belt system’s overall performance and lifespan. Consider the following tips when dealing with wear and damage:

1. Consult the manufacturer’s guidelines: ALWAYS refer to the manufacturer’s guidelines for proper maintenance procedures and technical specifications.

2. Repair minor damage: Address minor damage such as small tears, abrasions, or punctures promptly by patching the affected area or performing a cold vulcanised splice.

3. Replace belts with extensive damage: If a belt displays extensive damage, such as large tears or punctures, replacing it entirely may be necessary to avoid the increased risk of failure.

4. Partner with conveyor belt specialists: Working with an experienced conveyor belt specialist like Change Parts ensures you receive professional advice, tailored repair solutions, and timely replacement parts.

Conclusion

Effective conveyor belt maintenance, involving regular inspection, cleaning, and timely repair, is integral to the efficient and reliable operation of your facility’s conveyor belt system. By establishing a preventative maintenance program, applying essential inspection techniques, and adhering to best practices in cleaning and lubrication, you can reduce downtime and enhance productivity.

In addition to adopting these maintenance strategies, collaboration with conveyor belt specialists like Change Parts ensures access to expert advice, maintenance solutions, and replacement parts tailored to your facility’s unique requirements. Entrust your conveyor belt maintenance to a dedicated partner focused on ensuring the optimal performance, longevity, and safety of your conveyor belt systems.

Ensure the sustained efficiency, reliability, and lifespan of your conveyor belt systems with the assistance of Change Parts. Get in touch with our team of conveyor belt specialists today to discuss your maintenance needs and let us provide insights, support, and tailored solutions that keep your facility running smoothly and productively.