In the food manufacturing industry, choosing the right conveyor belt system is essential for maintaining operational efficiency, productivity, and compliance with strict food safety regulations. Stainless steel conveyor belts offer an ideal solution for many food processing applications, combining exceptional durability, hygiene, and resistance to harsh manufacturing environments. With their easy-to-clean design and resistance to corrosion and temperature variations, stainless steel belts have become popular for many food manufacturers seeking a reliable and high-performing conveyor belt solution.

Understanding the benefits and unique qualities of stainless steel conveyor belts is crucial for making informed decisions that elevate your food manufacturing operation to new heights of success. In this comprehensive guide, we will explore the advantages of stainless steel conveyor belts and delve into the essential factors to consider when selecting the perfect stainless steel belt for your specific food manufacturing processes. By analysing aspects such as belt design, required maintenance, and compliance with food safety standards, you can confidently invest in a stainless steel conveyor belt system that drives your facility’s efficiency, productivity, and food safety compliance.

Key Benefits of Stainless Steel Conveyor Belts

Before diving into the specifics of selecting the perfect stainless steel conveyor belt for your food manufacturing operation, it’s essential to understand the key benefits these belts offer:

1. Exceptional Durability: Stainless steel is a highly durable material with a natural resistance to corrosion, wear, and temperature variations. This ensures the longevity of your conveyor belt system, reducing the need for frequent repairs or replacements.

2. Hygienic and Easy-to-Clean: Stainless steel’s non-porous and smooth surface allows for easy cleaning and quick sanitation, making it an ideal solution for maintaining strict food safety standards.

3. Adaptability to Varied Manufacturing Environments: Stain steel’s inherent strength and temperature resistance enable these conveyor belts to be used in high-temperature, high-moisture, or corrosive environments without compromising performance.

Factors to Consider When Choosing the Right Stainless Steel Belt

Now that you understand the benefits of stainless steel conveyor belts, it’s important to consider various factors in selecting the ideal belt for your specific food manufacturing processes:

1. System Compatibility: Ensure that the stainless steel belt you choose is compatible with your existing conveyor system and your specific food manufacturing process and equipment.

2. Product Type and Requirements: Consider the nature of the food products being processed, including weight, size, shape, and temperature requirements. The chosen belt should be able to accommodate these product characteristics without affecting operational efficiency or food safety.

3. Compliance with Regulations and Standards: Choosing a stainless steel conveyor belt that complies with the relevant food manufacturing safety regulations and industry standards is crucial, ensuring the ongoing protection of food quality and consumer safety.

Stainless Steel Belt Design Options

Various stainless steel belt design options are available to cater to different food manufacturing applications:

1. Flat Wire Belts: Featuring a woven design of flat wire spirals, these belts offer a large open area, making them suitable for food processing applications that require high levels of ventilation, drainage, or moisture removal.

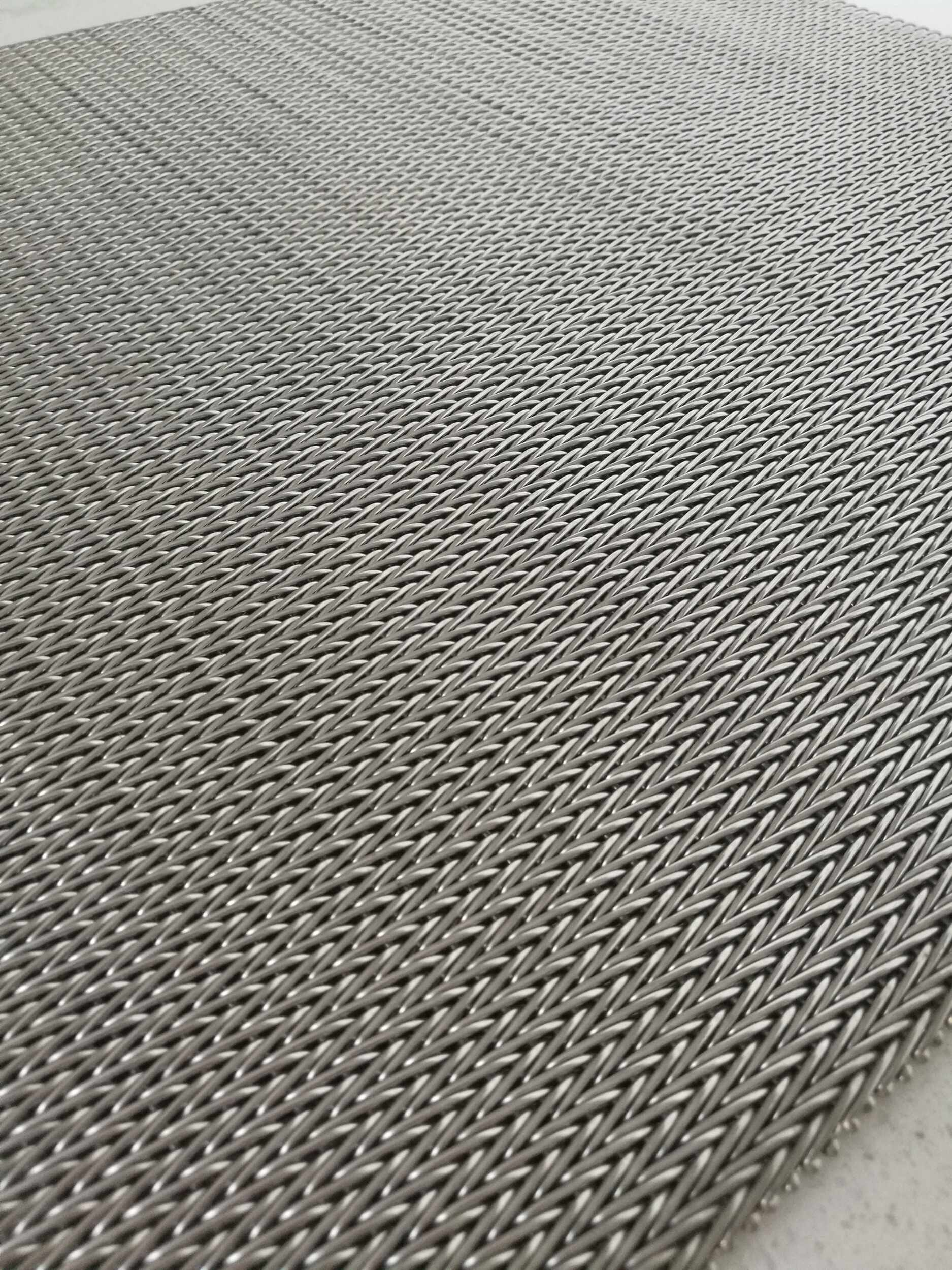

2. Balanced Weave Belts: Constructed from a series of interwoven wire spirals, balanced weave belts provide a versatile, flexible, and strong solution for a wide range of food manufacturing processes.

3. Chain-Driven Belts: Chain-driven stainless steel belts offer enhanced strength and durability, making them ideal for heavy-duty applications or those requiring precise belt positioning.

Maintenance and Cleaning Considerations

The maintenance and cleaning requirements of a stainless steel conveyor belt can influence its long-term efficiency and performance in your food manufacturing operation:

1. Cleaning Protocols: Frequent and thorough cleaning of stainless steel conveyor belts is essential for maintaining hygiene standards and preventing product contamination or cross-contamination between production runs. Develop a regular cleaning schedule that includes both routine daily cleaning and more comprehensive deep-cleaning procedures.

2. Preventative Maintenance: To ensure the longevity and optimal performance of your stainless steel conveyor belt, implement a preventative maintenance schedule that includes regular inspections, lubrication, and adjustments as needed.

3. Troubleshooting and Repairs: While stainless steel conveyor belts are known for their durability, they may require occasional repairs or adjustments to maintain peak performance. Make sure to address any apparent issues promptly to minimise disruptions to your food manufacturing operation.

Conclusion

Investing in stainless steel conveyor belts can significantly enhance your food manufacturing operation’s efficiency, productivity, and food safety. By carefully considering factors such as system compatibility, product requirements, regulatory compliance, belt design, and maintenance requirements, you can select the perfect stainless steel belt solution tailored to your specific manufacturing processes.

Embark on your journey to finding the ideal stainless steel conveyor belt for your food manufacturing operation with Change Parts Pty Ltd. Contact our team of experts today for personalised guidance, high-quality conveyor belts, and comprehensive support, empowering you to make the best possible choice for your business and secure your competitive advantage in the rapidly evolving food manufacturing sector.