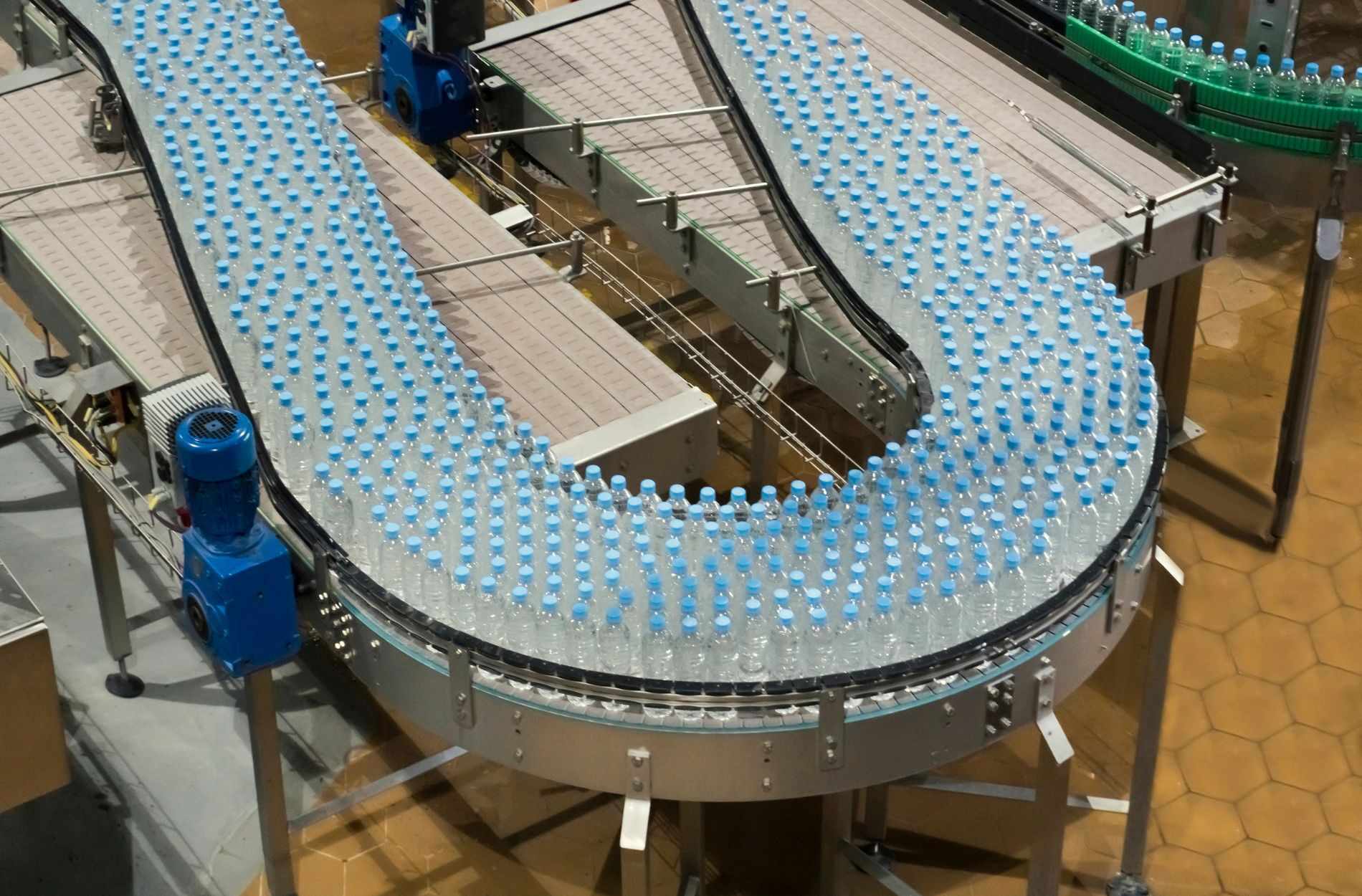

In the realm of conveyor belt systems, Balanced Weave Chain Drive Belts offer a unique combination of attributes that make them highly sought-after in various industries. These belts provide an excellent balance of strength, flexibility, and durability, enabling them to effectively transport a wide range of products with ease and precision. In this comprehensive guide, we will delve into the world of Balanced Weave Chain Drive Belts, bringing to light their unique features, ideal applications, potential industries, and crucial maintenance practices that will ensure their optimal performance and longevity.

Balanced Weave Chain Drive Belts are constructed by intricately weaving spiral wires around chains, creating a belt with a balanced and stable structure. This design ensures smooth product handling and effectively prevents belt-tracking issues, making them an excellent choice for a variety of industries. The chain drive system offers enhanced strength, allowing these belts to handle heavier loads with ease, making them suitable for both light and heavy-duty applications.

One of the main advantages of Balanced Weave Chain Drive Belts is their adaptability and customisation options. These belts can be tailored to suit the specific needs of your conveyor system, such as varying mesh sizes, wire diameter, and chain configurations, ensuring optimal performance in your unique environment.

In addition to their commendable features and versatility, Balanced Weave Chain Drive Belts also offer ease of maintenance. By adhering to the recommended maintenance practices, you can ensure that your Balanced Weave Chain Drive Belt delivers smooth and efficient operation, minimising downtime and maximising productivity.

In this guide, we will delve further into the fascinating world of Balanced Weave Chain Drive Belts, highlighting their diverse applications, suitable industries, and maintenance guidelines. This knowledge will empower you to make an informed decision about whether Balanced Weave Chain Drive Belts are an ideal solution for your conveyor system, and how to maintain them for optimal performance.

Unique Features and Benefits of Balanced Weave Chain Drive Belts

Exceptional Strength and Load Capacity

One of the key features of Balanced Weave Chain Drive Belts is their impressive strength and load capacity, facilitated by the chain drive system. This attribute enables them to handle heavier loads with ease, making them ideal for both light and heavy-duty applications across various industries.

Smooth Product Handling

The intricate weaving of spiral wires around chains in Balanced Weave Chain Drive Belts results in a balanced and stable structure. This design ensures smooth product handling and effectively prevents belt tracking issues, contributing to efficient and reliable product transportation.

Customisation and Versatility

Balanced Weave Chain Drive Belts boast unrivalled versatility, as they can be tailored to meet the specific requirements of your conveyor system. With options like varying mesh sizes, wire diameter, and chain configurations, these belts can be customised to cater to the unique needs of your industry and application, ensuring optimal performance and functionality.

Ease of Maintenance

In addition to their exceptional strength, Balanced Weave Chain Drive Belts are also known for their ease of maintenance. By adhering to recommended maintenance practices, you can ensure the smooth and efficient operation of your belts, minimising downtime, and maximising productivity.

Industries and Applications Suited to Balanced Weave Chain Drive Belts

Food Processing

Balanced Weave Chain Drive Belts are an excellent choice for the food processing industry. Their strength and smooth product handling capabilities make them ideal for applications involving baking, frying, cooling, and freezing processes. Additionally, their customisation options allow for tailor-made solutions that cater to specific food processing requirements.

Automotive Manufacturing

In the automotive manufacturing sector, Balanced Weave Chain Drive Belts are commonly used for parts handling, assembly, and painting processes. Their exceptional strength and flexibility enable them to transport various automotive components with precision and care, optimising production workflows and improving overall efficiency.

Pharmaceutical Production

Balanced Weave Chain Drive Belts offer numerous advantages in the pharmaceutical production industry as well. Their strength, customisation options, and smooth product handling make them suitable for processes such as tablet compression, capsule filling, and blister packaging. Furthermore, their maintenance-friendly design ensures minimal downtime during crucial production operations.

General Manufacturing and Assembly

Balanced Weave Chain Drive Belts are also ideal for general manufacturing and assembly applications. Their versatility and customisation options make them suitable for a wide range of processes, including the transportation of electronic components, assembly of consumer goods, and handling of bulk materials.

Essential Maintenance Practices for Balanced Weave Chain Drive Belts

Regular Inspections and Monitoring

To maintain the optimal performance and longevity of your Balanced Weave Chain Drive Belt, it’s critical to perform regular inspections and monitor its operation. Check for signs of wear and damage, such as worn or broken chains and wires, and address any issues promptly to avoid costly downtime and prolong the belt’s service life.

Tension and Tracking Adjustments

Maintaining proper tension and tracking in your Balanced Weave Chain Drive Belt is essential for its overall performance and longevity. Ensure that your belt is tensioned correctly, as recommended by the manufacturer, and regularly monitor and adjust tracking to maintain efficient operation and prevent premature wear.

Cleaning and Debris Removal

Regular cleaning is vital for maintaining the performance and efficiency of your Balanced Weave Chain Drive Belt. Periodically remove debris and product buildup using approved cleaning methods for your specific belt material and application. This practice will not only preserve the belt’s performance but also promote a hygienic work environment, particularly in industries with strict cleanliness requirements.

Chain and Wire Replacement

Over time, chains and wires within your Balanced Weave Chain Drive Belt may wear and require replacement. By closely monitoring the condition of your belt and replacing worn components as necessary, you can maintain optimum performance and efficiency and minimise the risk of unexpected downtime.

Boost Your Conveyor System’s Efficiency with Balanced Weave Chain Drive Belts

Balanced Weave Chain Drive Belts offer a unique combination of strength, flexibility, and adaptability that make them an ideal solution for various industries and applications. By gaining a deeper understanding of their features and benefits and implementing effective maintenance practices, you can ensure their optimal performance and extended service life.

Whether you work in food processing, automotive manufacturing, pharmaceutical production, or general manufacturing and assembly, Balanced Weave Chain Drive Belts have the potential to elevate the efficiency of your conveyor system and streamline your production processes. Embrace the outstanding features and performance of Balanced Weave Chain Drive Belts to optimise your conveyor system and boost your productivity. Visit the website of Change Parts Pty Ltd for more information.