In the diverse landscape of industrial conveyor systems, Uniflex Conveyor Belts stand out for their exceptional flexibility and efficiency. These belts offer a range of features that make them especially suited for certain industries and applications, providing optimal product handling and transportation. In this comprehensive guide, we will explore the exciting world of Uniflex Conveyor Belts, shedding light on their unique features, suitable industries, best applications, and effective maintenance practices to ensure top-notch performance and extended service life.

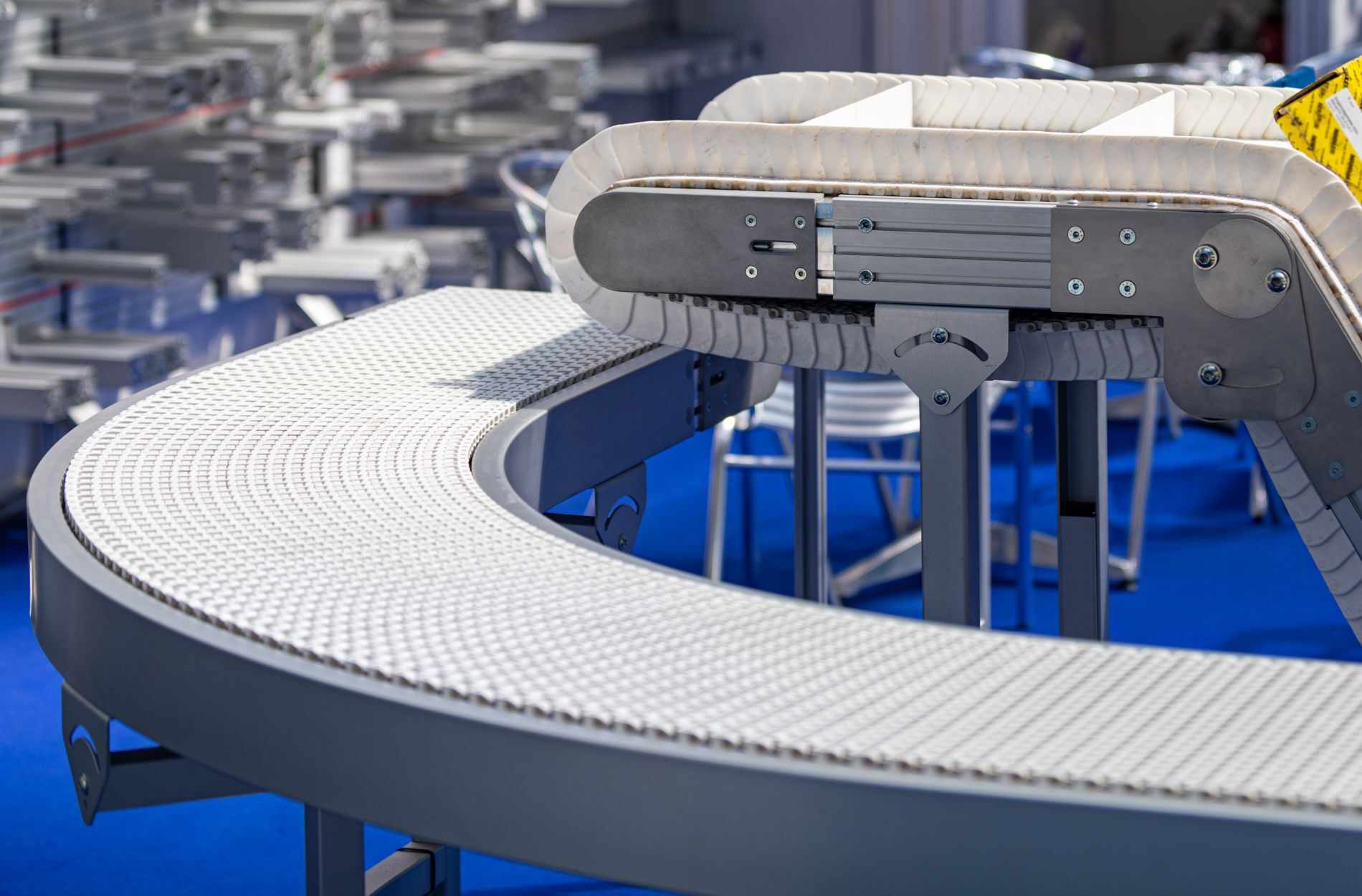

Uniflex Conveyor Belts are characterised by their unique construction, which involves interwoven metal links that create a flexible yet stable belt. This design allows the belt to conform to various shapes and contours, providing optimal product handling in a variety of applications. Furthermore, the open structure of Uniflex Conveyor Belts ensures excellent airflow, making them ideal for applications requiring drying or cooling processes.

One of the major selling points of Uniflex Conveyor Belts is their incredible versatility. They can be customised to meet the specific needs of your conveyor system, with options such as various mesh sizes, materials, and accessories to further enhance their functionality. This adaptability makes Uniflex Conveyor Belts an excellent choice for a wide range of industries, including food processing, automotive manufacturing, pharmaceutical production, and more.

In addition to their exceptional features and customisation options, Uniflex Conveyor Belts are also known for their ease of maintenance. By adhering to the recommended maintenance practices, you can ensure that your Uniflex Conveyor Belt continues to operate smoothly and efficiently, minimising downtime and maximising productivity.

In this guide, we will delve further into the many benefits and applications of Uniflex Conveyor Belts, and provide essential tips to maintain their performance and longevity. With this knowledge in hand, you will be well-equipped to make informed decisions about whether Uniflex Conveyor Belts are the perfect solution for your conveyor system and how to keep them operating at peak efficiency.

Unique Features and Benefits of Uniflex Conveyor Belts

Incredible Flexibility

One of the main attractions of Uniflex Conveyor Belts is their remarkable flexibility. The unique construction, which consists of interwoven metal links, enables the belt to conform to various shapes and contours. This flexibility offers exceptional product handling and support, making Uniflex Conveyor Belts an ideal choice for a wide range of applications.

Customisation and Versatility

Uniflex Conveyor Belts boast unrivalled versatility, as they can be fully customised to meet the specific requirements of your conveyor system. With options such as various mesh sizes, materials, and accessories, Uniflex Conveyor Belts can be tailored to the unique needs of your industry, ensuring optimal performance and functionality.

Excellent Airflow and Temperature Management

The open structure of Uniflex Conveyor Belts ensures superior airflow, which is beneficial for applications requiring drying or cooling processes. This feature not only contributes to improved product handling but also assists in maintaining optimal temperatures for efficient operations.

Ease of Maintenance

In addition to their exceptional features, Uniflex Conveyor Belts are also known for their ease of maintenance. By adhering to the recommended maintenance practices, you can ensure that your Uniflex Conveyor Belt continues to operate smoothly and efficiently, minimising downtime and maximising productivity.

Industries and Applications Excelling with Uniflex Conveyor Belts

Food Processing

Uniflex Conveyor Belts are a perfect match for the food processing industry, where their flexible nature and excellent temperature management shine. They are ideal for applications involving baking, frying, and cooling processes, where their unique design ensures optimal product handling and even temperature distribution.

Automotive Manufacturing

In automotive manufacturing, Uniflex Conveyor Belts are commonly used for parts handling, assembly, and various finishing processes. Their versatility and customisation options allow them to cater to the specific requirements of automotive manufacturing facilities, transporting various components with precision and care.

Pharmaceutical Production

Uniflex Conveyor Belts offer numerous advantages to the pharmaceutical industry as well. Their flexibility, temperature management capabilities, and customisation options make them ideal for tablet presses, blister packaging, and other pharmaceutical production processes, where they can efficiently and safely handle delicate products.

General Manufacturing

In general manufacturing facilities, Uniflex Conveyor Belts provide a reliable, versatile, and efficient product handling solution. Their adaptability makes them well-suited for a wide range of applications, from the transportation of small electronic components to the handling of larger, more substantial items.

Essential Maintenance Tips for Uniflex Conveyor Belts

Regular Inspections and Monitoring

To keep your Uniflex Conveyor Belt in top condition, it’s crucial to perform regular inspections and monitor its performance. Check for signs of wear and damage, such as loose or broken links, and address any issues promptly to avoid costly downtime and prolong the belt’s service life.

Tension and Tracking Adjustments

Maintaining proper tension and tracking in your Uniflex Conveyor Belt is critical to its overall performance and longevity. Ensure that your belt is tensioned correctly, as recommended by the manufacturer, and regularly monitor and adjust the tracking to maintain smooth, efficient operation.

Cleaning and Debris Removal

Regular cleaning is essential for maintaining the performance and efficiency of your Uniflex Conveyor Belt, especially in industries with strict hygiene requirements. Periodically remove debris and product build-up, using approved cleaning methods for your specific belt material and application.

Component Replacement

Over time, components of your Uniflex Conveyor Belt may wear and require replacement. By closely monitoring the condition of your belt and its components, and replacing parts as necessary, you can maintain the performance and efficiency of your conveyor system, reducing the risk of unexpected downtime.

Optimise Your Conveyor System with Uniflex Conveyor Belts

Uniflex Conveyor Belts offer unparalleled flexibility, efficiency, and versatility that are well-suited to a range of industries and applications. By understanding the unique features of these belts, implementing them in suitable settings, and adhering to essential maintenance practices, you can optimise your conveyor system’s performance and extend its service life.

Whether you work in food processing, automotive manufacturing, pharmaceutical production, or general manufacturing, investing in Uniflex Conveyor Belts and maintaining them properly will help you achieve efficient, effective, and reliable product handling within your facility. Unlock the potential of Uniflex Conveyor Belts and elevate the performance of your conveyor system to new heights. Visit the website of Change Parts Pty Ltd to learn more.