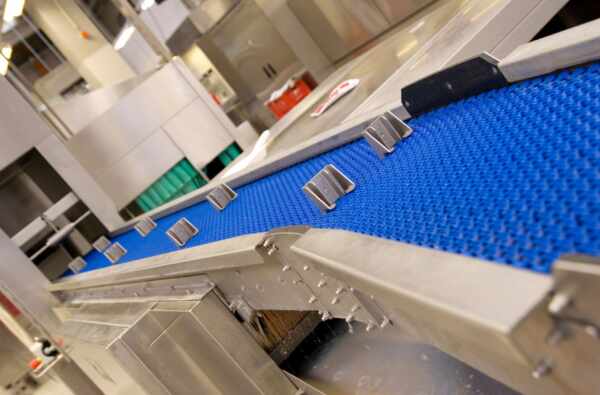

The conveyor belt system is vital to your food manufacturing facility, impacting productivity, efficiency, and adherence to food safety standards. As your conveyor system ages, it inevitably experiences wear and tear or even suffers from breakdowns that can impact the performance of your production line. As a responsible manager, it’s crucial to identify when your system requires repairs or upgrades, ensuring you maintain the highest level of efficiency and food safety.

In this comprehensive guide, we will help you assess your current conveyor belt system and determine whether it’s time to repair or replace parts to maintain an efficient and hygienic food manufacturing facility. We will discuss the factors to consider when evaluating your system, including belt condition, alignment, mechanical parts, and overall performance. Equipped with this knowledge, you can determine if your conveyor system requires routine maintenance, targeted repairs, or a complete overhaul.

We will also explore the benefits and drawbacks of repairing versus replacing conveyor belts, covering aspects such as cost, reliability, and food safety. Ultimately, we aim to provide you with the tools and understanding necessary to make informed decisions when it comes to maintaining your conveyor belt system’s health. Furthermore, we will highlight the importance of collaborating with trusted conveyor belt suppliers, like Change Parts Pty Ltd, to access expert guidance and quality products to support your food manufacturing facility’s success in the long run.

Monitoring, repairing, and replacing conveyor belt system parts can be a daunting task, but it is essential to ensure the smooth functioning of your food manufacturing facility. By following the valuable insights in this guide, you can make informed decisions and keep your facility operating at peak efficiency.

Upgrading Your Food Manufacturing Facility: Conveyor Belt Repair or Replacement?

Assessing Your Conveyor Belt System

To determine if your conveyor belt system requires repairs or replacements, it’s crucial first to evaluate its current state and performance. Here are some factors to consider when assessing your conveyor belt system:

1. Belt Condition: Inspect the conveyor belt’s surface and edges for signs of wear, damage, or fraying. Breakage or disintegration of the belt material can lead to inefficiencies and require immediate attention.

2. Belt Alignment: Misaligned belts can result in uneven wear, damage, and performance issues. Check your conveyor system’s alignment and ensure it’s running straight and true, especially in the areas of pulleys and idlers.

3. Mechanical Components: Examine rollers, bearings, and drive components for signs of wear, corrosion, or damage. Mechanical issues can impact system performance, causing inefficiencies and potential breakdowns.

4. System Performance: Observe your conveyor belt system’s overall performance, noticing any changes in speed, efficiency, or noise levels. Unusual behaviour or inconsistencies may indicate underlying issues that need addressing.

Repair or Replace: Weighing the Options

After evaluating your conveyor belt system, you can decide whether to repair or replace parts or the entire system. Consider the following when making your decision:

1. Cost: Repairing conveyor belts can often be less expensive in the short-term. However, continually replacing worn or damaged belts may eventually add up and cost more than investing in a new system.

2. Reliability: While repairs can temporarily restore a conveyor system’s functionality, replacement parts or a new conveyor belt system may offer a more reliable and long-lasting solution, minimizing future downtime.

3. Food Safety: Damaged conveyor belts can pose hygiene risks, which are detrimental to food manufacturing facilities. Replacing belts or components ensures that food safety is maintained to the highest standards.

4. Efficiency: Upgrading to a new conveyor belt system may provide improved efficiency and increased productivity, providing long-term benefits to your facility.

Advantages of Conveyor Belt Repair

1. Cost-effective: Repairing damaged belts or components can often be more budget-friendly than replacing the entire system.

2. Faster turnaround: Repair work can often be completed more quickly, reducing downtime and minimising disruptions to your production line.

3. Resource conservation: Repairing existing belts prolongs their life and contributes to more sustainable resource use by reducing waste.

4. Flexibility: Repairs can be targeted to specific issues, allowing you to address problems without overhauling the entire conveyor belt system.

Advantages of Conveyor Belt Replacement

1. Improved reliability: Replacing a worn or damaged conveyor belt with a new one can increase system reliability, reducing the likelihood of future breakdowns and the need for ongoing repairs.

2. Enhanced performance: Upgrading to a new conveyor belt system may offer better performance, higher efficiency, and increased productivity.

3. Compliance with food safety standards: New conveyor belts typically meet more stringent food safety standards, ensuring your manufacturing facility upholds hygienic practices.

4. Lower long-term maintenance costs: Investing in a new conveyor belt system may result in lower maintenance costs over time, as new systems often require less frequent repairs.

Partnering with a Trusted Conveyor Belt Supplier

Whether you decide to repair or replace your conveyor belt system, partnering with a trusted conveyor belt supplier like Change Parts Pty Ltd can provide invaluable support throughout the process. With expertise in various conveyor belt types, components, and applications, industry professionals can guide you in making the right decisions for your food manufacturing facility.

In addition to supplying high-quality products, experienced conveyor belt suppliers can also offer valuable services such as installation, maintenance, troubleshooting, and technical support, ensuring your system operates smoothly and efficiently.

Conclusion

Determining whether to repair or replace your conveyor belt system is a critical decision that can significantly impact your food manufacturing facility’s efficiency, productivity, and food safety standards. Assessing your conveyor system, considering the advantages of repair versus replacement, and partnering with a trusted conveyor belt supplier can help you make well-informed decisions regarding your facility’s conveyor belt system maintenance.

By following the insights provided in this guide, you can ensure a smooth and efficient conveyor belt system that supports the long-term success and growth of your food manufacturing facility.

If your conveyor belt system requires repair or replacement, look no further than Change Parts Pty Ltd. Contact us today for expert advice, top-quality products, and dedicated support to optimise your food manufacturing facility’s conveyor belt system.