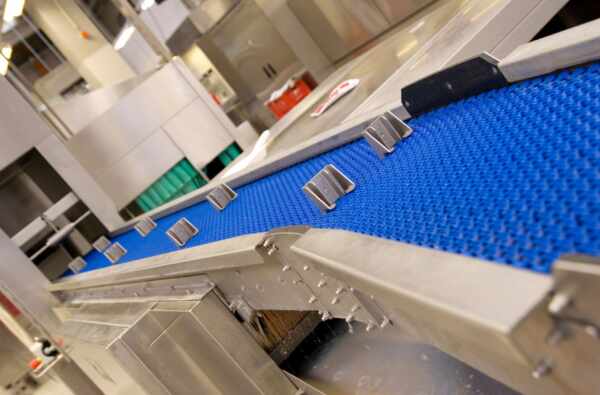

In today’s fast-paced industrial landscape, effective conveyor systems are crucial for efficiently moving goods and materials throughout a facility. Among the various types of conveyor belts available, Flat Flex Conveyor Belts offer a unique combination of features and advantages that cater to various industries and applications. In this article, we will delve into the world of Flat Flex Conveyor Belts, exploring their distinctive characteristics, how they benefit different sectors, and essential maintenance practices to ensure optimal performance and durability.

Flat Flex Conveyor Belts are constructed of multiple strands of stainless steel wire joined together in a bricklay pattern, providing a strong yet flexible surface for transporting products. These belts offer exceptional load-bearing capacity and can be customised with various mesh sizes to accommodate a wide range of product sizes and weights. Additional features include optional side flights or edge guards, which can be added to prevent product spillage during transportation.

One notable advantage of Flat Flex Conveyor Belts is their versatility. The belts can be designed with different mesh openings to suit specific product handling requirements, allowing them to be easily tailored to various applications across industries. Flat Flex Conveyor Belts are also known for their resistance to high temperatures, chemical exposure, and corrosion, making them suitable for use in challenging industrial environments.

Industries where Flat Flex Conveyor Belts are commonly employed include food processing, packaging, and manufacturing facilities, where they are used for applications such as baking, frying, cooling, freezing, and sorting. Due to their uniform surface, Flat Flex Conveyor Belts can provide precise product positioning, making them highly suited to applications requiring accuracy and efficiency.

Proper maintenance is vital to ensure the Flat Flex Conveyor Belt continues to perform at its best. Regular inspections, tension adjustments, alignment checks, cleaning, and timely replacement of worn components can contribute to reduced downtime, improved efficiency, and extended belt lifespan.

In this comprehensive guide, we will examine the features, applications, and maintenance of Flat Flex Conveyor Belts in greater detail, equipping you with the knowledge to optimise the performance and efficiency of your conveyor system.

Key Features of Flat Flex Conveyor Belts

Customisable Mesh Sizes

Flat Flex Conveyor Belts offer excellent adaptability to handle various product sizes and weights. With the option to customise the mesh size, these belts can be tailored to meet the needs of specific applications, ensuring seamless integration into your conveyor system.

High Temperature and Chemical Resistance

Constructed from stainless steel, Flat Flex Conveyor Belts boast remarkable resistance to high temperatures, making them suitable for applications involving heat processing, such as baking or frying. Moreover, their resistance to chemicals and corrosion ensures that they can withstand harsh industrial environments while maintaining optimal performance.

Optional Side Flights and Edge Guards

Flat Flex Conveyor Belts can be fitted with optional side flights or edge guards to prevent product spillage during transportation. These additions not only improve the efficiency of your conveyor system but also help maintain a clean and safe working environment.

Precise Product Positioning

The uniform surface of Flat Flex Conveyor Belts enables precise product positioning throughout the transportation process. This feature is particularly beneficial in applications where accuracy and efficiency are crucial, such as assembly lines or sorting processes.

Applications Across Industries

Food Processing and Packaging

Flat Flex Conveyor Belts are widely used in the food processing and packaging industries. Their high temperature and chemical resistance make them ideal for applications like baking, frying, cooling, and freezing. Additionally, the option to customise mesh sizes ensures a perfect fit for various product handling requirements, contributing to the hygiene and efficiency of food-related processes.

Manufacturing and Assembly

Flat Flex Conveyor Belts provide reliable and precise product positioning in manufacturing and assembly line applications. Their customisable mesh sizes and optional side flights allow them to accommodate a broad range of products, from small electronics to heavy automotive components. These features, combined with their chemical and temperature resistance, make Flat Flex Conveyor Belts an excellent option for manufacturing facilities.

Sorting and Distribution Facilities

Flat Flex Conveyor Belts are also commonly used in sorting and distribution facilities, where accurate product positioning and a hard-wearing conveyor system are essential. Their customisable design, uniform surface, and robust construction enable them to effectively handle the demands of sorting and distribution environments while maintaining efficient processing times.

Maintaining Your Flat Flex Conveyor Belt

Regular Inspections

To ensure optimal performance and longevity, it’s crucial to inspect your Flat Flex Conveyor Belt regularly. Look for signs of wear, such as frayed edges, broken wires or damaged mesh openings. Addressing these issues promptly can help minimise downtime and extend the lifespan of your belt.

Adjusting Tension

Maintaining the appropriate tension on your Flat Flex Conveyor Belt is fundamental to its performance. Proper tensioning ensures smooth operation and prevents uneven wear on both the belt and the conveyor system. Follow the manufacturer’s recommendations for tension adjustments to avoid belt slippage and tracking issues.

Alignment Checks

Ensuring proper alignment of your Flat Flex Conveyor Belt contributes to its efficient and smooth operation, reducing the likelihood of tracking issues and uneven wear. Regularly check that your conveyor belts and sprockets are properly aligned to prevent any potential problems.

Cleaning

Maintaining a clean Flat Flex Conveyor Belt is vital for optimal performance, particularly in industries where hygiene is paramount, such as food processing and pharmaceuticals. Regular cleaning will prevent the buildup of dirt, grease and other contaminants that can affect product quality and conveyor efficiency. Use a mild detergent and water or an industry-approved cleaner as required.

Replacement of Worn Components

Over time, components of your Flat Flex Conveyor Belt may experience wear and need replacement. Monitor the condition of your belt and replace worn components as necessary to maintain the performance and efficiency of your conveyor system.

Enhance Your Conveyor System with Flat Flex Conveyor Belts

Flat Flex Conveyor Belts offer numerous features and benefits that make them an ideal choice for a wide range of industries and applications. By understanding the unique advantages these belts provide and putting in place effective maintenance practices, you can ensure the performance and longevity of your conveyor system.

Whether you are in the food processing, manufacturing, or sorting and distribution industries, investing in Flat Flex Conveyor Belts and maintaining them properly will help you achieve efficient, effective, and reliable product transportation within your facilities. Visit the website of Change Parts Pty Ltd for more information.