Spiral Wire Belt

Spiral Wire Belt from Change Parts can be used in a variety of settings. The range of mild steel or stainless steel spiral wire belts are used in many industries and are most popular in the food processing industry and heat treatment.

Spiral conveyors provide smooth and continuous vertical transfer of products. Further, the mild steel conveyor is versatile and assists in the transport of items for example, cans and bottles, cartons, fresh produce, shrink wrapped items, cases and more. In Addition, the low friction chain supported bearings glide on a polyurethane guided surface. As a result, this allows for a safe, high speed and smooth operation with low noise and extreme durability.

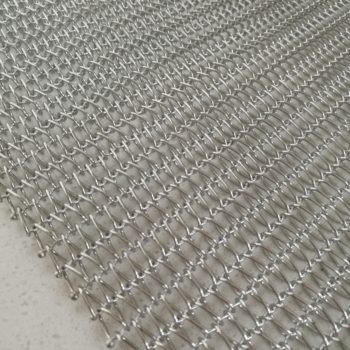

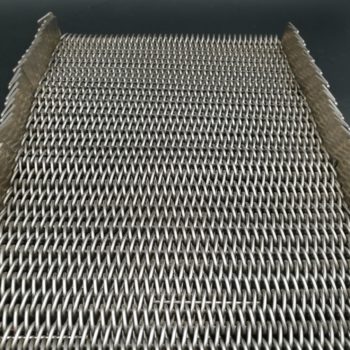

Spiral steel belts can be manufactured to sustain high temperature alloys like inconel 601. The spiral wire ranges include woven spiral wire such as Balance, Gratex, Cormel, Duplex, Chain Driven, Lehr, Baking Band and One Direction.

The spiral wire range is great for food processing and high temperature use. Small aperture belts, friction driven and chain driven belts are available for manufactures requiring additional strength and control in the manufacturing process.

At Change Parts, we have specialist engineers who will attend site and design the most economical route for the conveyor system. In addition, they will provide a full layout and installation drawings. Our engineers are often involved at the concept stage for the project, helping our customers with system layouts and sourcing of third party equipment for the overall contract. We pride ourselves on giving technical guidance to ensure maximum efficiencies on the conveyor system. We are very familiar with the strict hygiene requirements which are necessary when supplying and installing equipment and conveyor systems for the food, drink and pharmaceutical industries.