In today’s highly competitive industrial landscape, the efficiency and reliability of a business’s material handling process are critical to maintaining productivity, reducing bottlenecks, and ensuring on-time deliveries. The core of any effective material handling system is a well-functioning conveyor belt tailored to the requirements of your specific industry. With a plethora of conveyor belt types and materials available in the market, selecting the right one for your applications can be a daunting task.

Join us as we explore the world of conveyor belt types and learn how partnering with Change Parts can help you attain cost-effective and efficient conveyor system solutions tailored to your industry’s unique requirements. Our extensive product range and industry expertise give us a leading edge in delivering conveyor belts suitable for diverse applications and industries, further solidifying our reputation as a trusted conveyor solutions partner.

Key Factors to Consider for Conveyor Belt Selection

1. Product Characteristics

When selecting the right conveyor belt type for your industry, consider factors such as the size, weight, shape, and temperature of the products being handled. It’s crucial to choose a conveyor belt that provides optimal grip, texture, and material properties to accommodate your unique product requirements and prevent potential damage or losses during the conveying process.

2. Environmental Conditions

The operating environment can significantly impact the performance and longevity of your conveyor belt. Factors such as temperature, humidity, exposure to chemicals, or abrasive materials should be taken into account when selecting a conveyor belt type suitable for your industry.

3. Maintenance and Durability

Ease of maintenance and durability are essential considerations to ensure the cost-effectiveness and efficiency of your conveyor system. Opt for conveyor belt types that require minimal maintenance and can withstand the wear and tear of rigorous operations to maximise reliability and minimise downtime.

Types of Conveyor Belts for Different Industries and Applications

1. Food Manufacturing and Conveyor Belts

Food manufacturing requires conveyor belts that can meet strict hygiene standards while effectively handling delicate products. Conveyor belts made from food-grade materials, such as FDA-approved PVC or polyurethane, are ideal for this industry. These belts provide excellent resistance to chemicals, water, and other contaminants, ensuring safe product handling and easy cleaning.

2. Packaging Industry

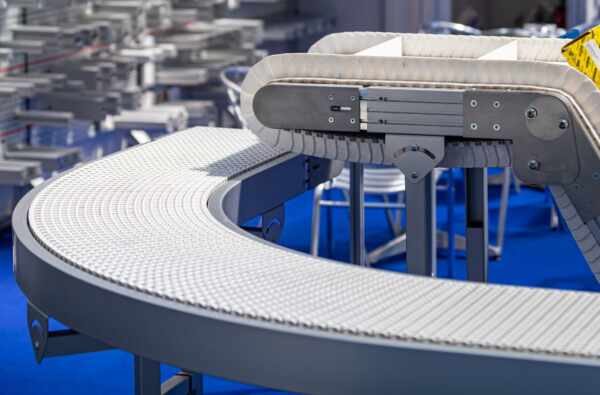

In the packaging industry, the conveyor belt must be adaptable to handle a wide variety of product sizes, shapes, and weights. Modular plastic conveyor belts are a popular choice due to their flexibility, durability, and ease of maintenance. These belts can easily be reconfigured to accommodate changing production needs and require minimal downtime when repairs are necessary.

3. Heavy-Duty Applications

For industries such as mining, construction, and aggregates, conveyor belts must be durable and robust to withstand harsh operating conditions and heavy loads. Steel belts are commonly used for these applications due to their exceptional strength and resistance to wear, impact, and tearing. These belts also have excellent heat and chemical resistance, making them suitable for use in high-temperature environments or with corrosive materials.

4. Specialised Conveyor Belt Types

Depending on the specific needs of your industry and application, specialised conveyor belt types may be required for optimal performance. Examples of these customised belting solutions include metal mesh belts for high-temperature applications, vacuum belts for fragile product handling, and magnetic belts for secure product transfer.

Replace or Repair: Ensuring the Longevity of Your Conveyor Belt System

1. Regular Inspections and Preventive Maintenance

Proactive maintenance is key to ensuring the longevity and reliability of your conveyor belt system. By regularly inspecting your belt for signs of wear, such as fraying, cracking, or delamination, and conducting preventive maintenance, you can identify potential issues before they escalate and address them to minimise downtime and costly repairs.

2. Prompt Repairs

If damages are detected during inspections, it’s essential to address them promptly to maintain the optimal performance of your conveyor system. In some cases, minor defects can be repaired on-site, while more severe damages may necessitate belt replacement.

3. Partner with Conveyor System Experts

Working with conveyor system experts who understand the unique challenges and requirements of your industry is critical to achieving the best results. They can provide valuable guidance and support in identifying the most appropriate conveyor belt types for your applications and implementing effective maintenance strategies.

Conclusion

Selecting the right conveyor belt for your industry and specific application needs requires careful consideration of factors such as product characteristics, operating environment, and ease of maintenance. By understanding the unique challenges and requirements of your industry, you can choose the most appropriate conveyor belt type to optimise your material handling processes and ensure long-term efficiency and reliability.

As an industry-leading conveyor solutions provider, Change Parts Pty Ltd offers a comprehensive range of conveyor belts designed to meet the challenges of various industries and applications. Partner with us to leverage our expertise and extensive product range, ensuring you always have the perfect conveyor belt solution tailored to your unique requirements.