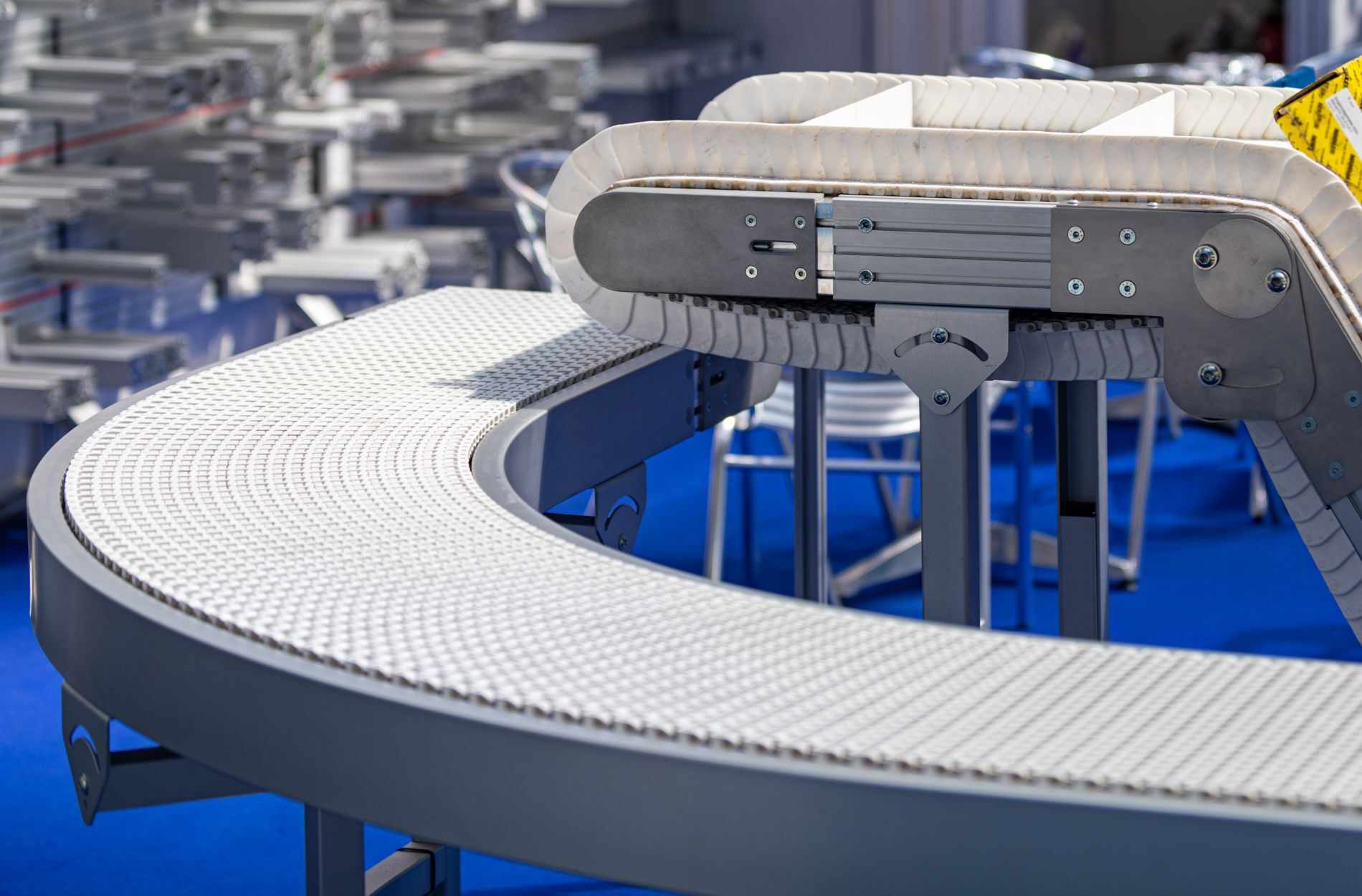

Conveyor belt systems are an integral part of many industrial facilities and are essential for improving productivity, streamlining processes, and reducing manual labour involvement. However, with the operation of such machinery comes the potential for accidents and injuries in the workplace. To prioritise the safety and wellbeing of your workforce, it’s vital to incorporate modern conveyor belt safety features that are designed to minimise these risks.

In this article, we’ll explore some of the most innovative conveyor belt safety features available today, looking at how these advancements can contribute to a safer and more secure work environment. From emergency stop controls and guardrail systems to intelligent sensors and machine vision technology, we’ll discuss the key safety features that can help protect your employees while ensuring smooth and efficient operation of your conveyor belt systems.

As we guide you through the various safety innovations, our aim is to equip you with the knowledge required to make informed decisions about the best safety features for your specific facility and conveyor system. Understanding the capabilities and benefits of these features can help you not only enhance workplace safety but also comply with industry regulations and maintain a strong safety track record.

So, join us on this enlightening journey as we delve into the world of conveyor belt safety features and examine how embracing modern safety technology can make a significant difference in your facility’s accident prevention efforts and overall safety culture. Stay ahead of the curve with the latest safety innovations for your conveyor belts from Change Parts Pty Ltd.

Modern Conveyor Belt Safety Features: Innovations for a Safer Workplace

Emergency Stop Controls

One of the most fundamental safety features for conveyor belt systems is the emergency stop control, designed to halt conveyor operation in the event of an accident or malfunction. These controls are typically activated via pull cords or push buttons placed at regular intervals along the conveyor, ensuring that workers have easy access to stop the conveyor belt when necessary. Some advanced systems also feature wireless or remote emergency stop controls, allowing authorised personnel to halt the conveyor’s operation from a safe distance.

Guardrail Systems and Protective Barriers

Guardrails and protective barriers are essential for preventing accidents caused by contact with moving conveyor belts, decreasing the risk of entanglement, pinching, or other injuries. These safety features can be constructed from various materials, including metal, plastic, or mesh, and are typically adjustable to suit different conveyor belt configurations. In addition to physical barriers, some facilities utilise light curtains or safety laser scanners to create virtual barriers around the conveyor, triggering an automatic stop when the designated safety zone is breached.

Intelligent Sensors

Incorporating intelligent sensors into your conveyor belt system can contribute significantly to workplace safety by monitoring various aspects of the conveyor’s performance and identifying potential hazards. These sensors can detect factors such as belt misalignment, irregular speed, excessive vibration, or elevated temperature, and can swiftly notify personnel if any red flags arise. This proactive approach allows your team to address potential issues before they escalate into serious problems, minimising the risk of accidents and prolonging the lifespan of your conveyor system.

Machine Vision Technology

Machine vision technology is an emerging trend in conveyor belt safety, utilising advanced cameras and software to monitor conveyor processes for potential issues or abnormal behaviour. By capturing high-resolution images of items on the conveyor and analysing them in real-time, this technology can identify and flag potential hazards, such as misplaced objects or damaged components, and trigger an automatic halt or alert workers to take action. By incorporating machine vision technology into your conveyor belt system, you can not only enhance safety but also streamline quality control and product inspection processes.

Tips for Implementing Effective Conveyor Belt Safety Features

– Conduct Regular Risk Assessments: Regularly assessing the potential hazards and risks associated with your conveyor belt systems can help you identify areas where new safety features may be necessary or existing ones can be improved.

– Invest in Employee Training: Regular training is essential for fostering a culture of safety in your workplace, ensuring that employees are well-versed in the correct operating procedures and are familiar with the conveyor belt safety features implemented in your facility.

– Stay Informed About Industry Standards and Regulations: Keep abreast of changes in industry regulations and standards related to conveyor belt safety, ensuring that your facility remains compliant and implementing necessary updates to your safety features.

– Prioritise Both Maintenance and Safety: Regular maintenance of your conveyor belt systems is key to ensuring their optimal performance and safety. By keeping your conveyor systems in good working order, you can minimise the risk of accidents and avoid costly downtime.

Embracing Conveyor Belt Safety Innovations

The importance of implementing advanced conveyor belt safety features in your facility cannot be overstated. By recognising the potential risks associated with conveyor belt systems and taking proactive steps to minimise these hazards, you can protect your workforce and maintain a safe, accident-free working environment.

With ongoing advancements in safety technology, there has never been a better time to explore and invest in innovative safety features for your conveyor belt systems. By partnering with Change Parts Pty Ltd, you can benefit from expert guidance and a comprehensive range of cutting-edge safety solutions tailored to your specific needs – ensuring that your facility remains at the forefront of conveyor belt safety.