Navigating the world of conveyor belts can be quite a task, especially when you have a myriad of options at your disposal. It’s like being in a candy shop with countless varieties to choose from, each with its unique flavour and appeal.

Well, guess what? We’ve got your back! This comprehensive guide seeks to demystify the process of choosing the right conveyor belt type for your specific needs. With the precision of a Swiss watchmaker, we’ll delve into the nitty-gritty of conveyor belts, from understanding their basic structure and function to exploring the different types available in the market.

Understanding the Different Types of Conveyor Belts

Before diving into the process of selecting the most suitable conveyor belt for your facility, it’s essential to have a strong understanding of the different types available. Here, we present an overview of some popular conveyor belt types and their key features:

1. Flat Belts: Flat conveyor belts are versatile and straightforward, consisting of a continuous band of material that moves between two pulleys. They can be made from a range of materials, such as rubber, PVC, or fabric, depending on the intended application.

2. Modular Plastic Belts: Made from interlocking plastic modules, these belts are highly durable and low maintenance. They are well suited for environments where sanitation is crucial, such as the food and beverage industry.

3. Steel Belts: Steel belts are known for their robustness and high load-bearing capacity, making them an ideal choice for heavy-duty and high-temperature applications in industries like metalworking and automotive manufacturing.

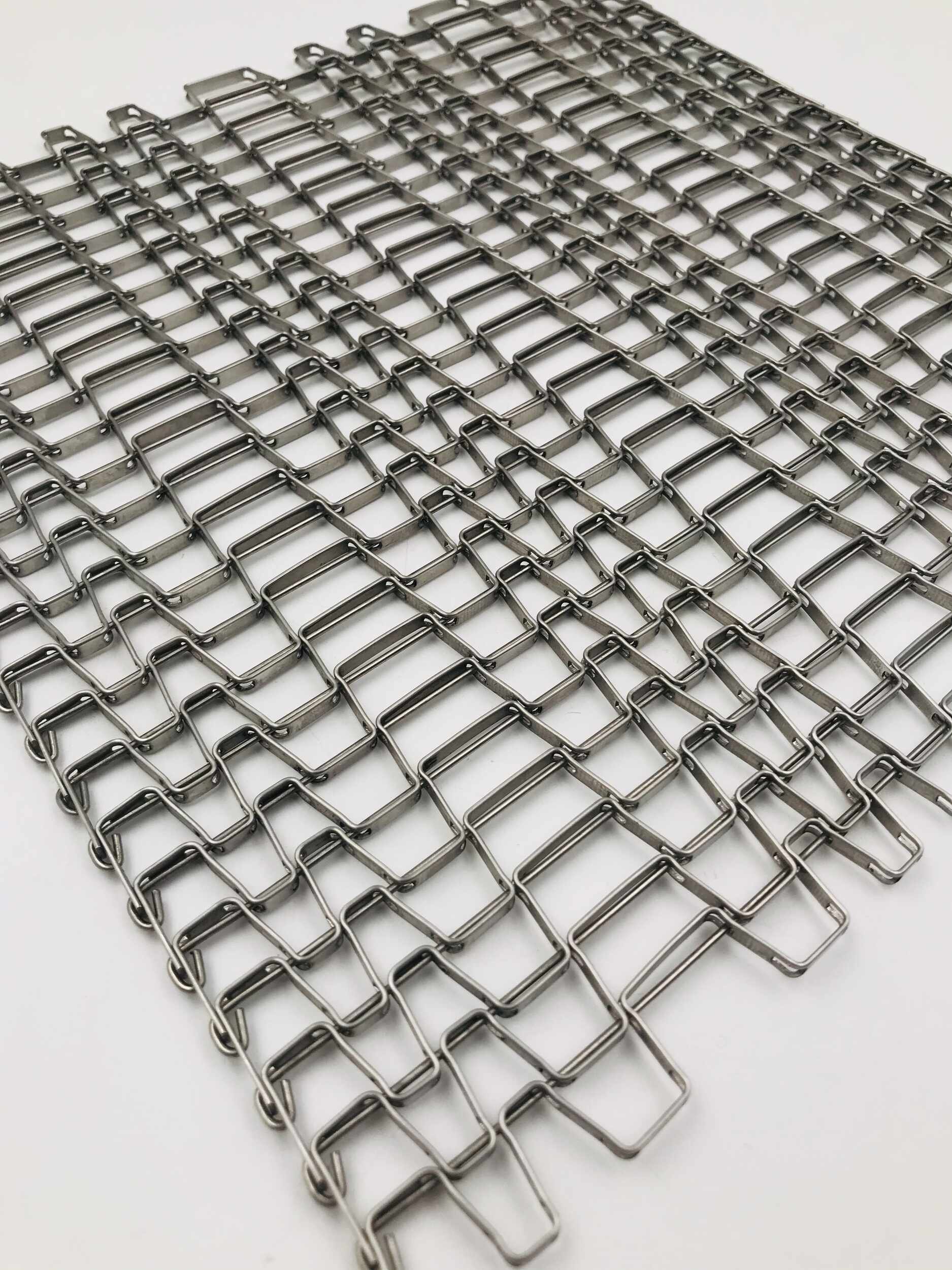

4. Specialty Conveyor Belts: There is a vast range of speciality conveyor belts designed for unique applications and environments, including magnetic belts for metal handling, vacuum belts for secure product transportation, and wire mesh belts for various industries.

Assessing Your Facility’s Requirements

The key to selecting the right conveyor belt type lies in thoroughly assessing the specific needs and conditions of your facility. Consider the following factors:

1. Material Handling: Evaluate the types of materials your conveyor system will be handling, including properties such as size, weight, and temperature. This will help you determine the appropriate belt material and load-bearing capacity.

2. Processing Environment: Consider the environment in which your conveyor system will be operating, taking into account factors like temperature, humidity, and chemical exposure. Ensure that the belt you choose can withstand these environmental conditions.

3. Industry Compliance: Ensure that your conveyor belt selection meets any industry-specific regulations or standards applicable to your facility. This is particularly important in industries where sanitation, safety, and product quality are paramount, such as food manufacturing or pharmaceuticals.

4. Future Growth: Factor in your facility’s future growth and expansion plans when selecting a conveyor belt. Choose a belt that has the flexibility and scalability to adapt to varying production requirements and material handling needs.

Comparing Suitable Conveyor Belt Types

Once you have thoroughly assessed your facility’s requirements, it’s time to compare the different conveyor belt types that meet your specific needs. Take the following attributes into account when making your comparison:

1. Durability: Assess the expected lifespan of each belt type, taking into account the frequency of use and the types of materials to be transported. A more durable belt type will ultimately reduce expenses related to maintenance and replacement.

2. Maintenance and Cleaning: Consider the ease of cleaning and maintaining each belt type, particularly in industries where sanitation and cleanliness are crucial. A belt that is simple to clean and maintain will contribute to improved productivity and efficiency.

3. Customisation Capabilities: Some conveyor belt types offer more customisation options than others, including variable belt widths, lengths, or material options. Choose a belt type that can be tailored to your facility’s unique requirements.

4. Cost Efficiency: While the initial cost of the conveyor belt is a critical factor, also consider the long-term cost implications. A seemingly cost-effective belt may not be the best financial choice in the long run if it has high maintenance demands or a lower lifespan.

Understanding the Importance of Choosing the Right Conveyor Belt

Take your time, do your research, consult with experts if necessary, and make an informed decision that best suits your operational needs. After all, the right conveyor belt can make a significant difference to your bottom line, and that matters a great deal.

If you’re seeking expert guidance on choosing the right type of conveyor belt for your facility, connect with our experienced team at Change Parts Pty Ltd today. We can help you find the perfect conveyor belt solution tailored to suit your specific needs and industry requirements, ensuring optimal performance and seamless operations.