In today’s dynamic global business landscape, companies across various industries are in constant pursuit of improved efficiency, reliability, and productivity in their operations. Conveyor belt systems have long been recognised as a cornerstone of modern manufacturing, warehousing, and distribution facilities, conveying materials and products seamlessly through production lines and storage areas.

However, with each industry facing unique challenges and requirements, it’s imperative to implement a conveyor belt solution tailored to address these specific needs, maximising efficiency and ensuring long-term success.

In this informative guide, we will explore the advantages of customising conveyor belt solutions for diverse industries, highlighting key considerations and best practices to ensure optimal efficiency, productivity, and reliability.

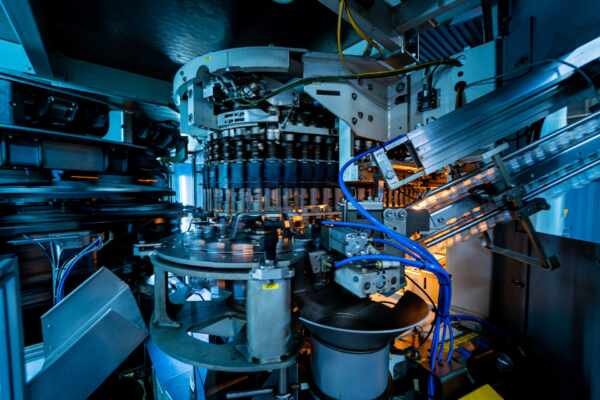

We will delve into the unique challenges faced by various industries, including mining, packaging, pharmaceuticals, and automotive, and discuss how tailored conveyor belt solutions can effectively address these needs, ensuring a streamlined and efficient operation.

With a wealth of expertise in providing customised conveyor belt solutions for a wide range of industries, Change Parts Pty Ltd is well-positioned to help businesses identify and implement the ideal conveyor belt systems to meet their unique challenges and goals.

Trust the experienced professionals at Change Parts Pty Ltd to provide the guidance, support, and solutions necessary to maximise efficiency and elevate your facility’s performance.

Understanding Unique Industry Challenges

Each industry has its distinct set of challenges and requirements, making it crucial to understand these nuances when designing and implementing a conveyor belt solution. Some common industry-specific challenges include:

- Mining: Conveyor belt solutions in the mining sector must withstand harsh operating conditions, including heavy loads, abrasive materials, and extreme temperatures, while maintaining operational efficiency, worker safety, and minimal downtime.

- Packaging: In the packaging industry, maintaining a high level of precision, speed, and cleanliness is essential, requiring conveyor belt systems that can adapt to various packaging materials, sizes, and shapes while ensuring minimal product damage.

- Pharmaceuticals: Conveyor belt solutions in the pharmaceutical industry must uphold stringent hygiene and cleanliness standards, facilitate precise handling of delicate products, and integrate seamlessly with various production processes, such as filling, labelling, and packaging.

- Automotive: Automotive manufacturing facilities require conveyor belt systems that can accommodate large and heavy components, as well as intricate assembly processes, ensuring a smooth and efficient production flow.

Customising Conveyor Belt Solutions for Industry-Specific Needs

To effectively address the unique challenges faced by different industries, taking a customised approach to conveyor belt solutions is essential. Key considerations for industry-specific customisations include:

- Material Selection: Choose the appropriate conveyor belt material based on industry requirements, considering factors such as durability, temperature resistance, and chemical resistance. For example, mining operations may benefit from robust rubber belts, while pharmaceutical facilities might require easy-to-clean, food-grade materials.

- Conveyor Belt Types: Select the right conveyor belt type to accommodate the unique demands of your industry, such as modular belts for versatile and easily reconfigurable systems, cleated belts for inclined material handling, or wire mesh belts for high-temperature environments.

- System Configurations: Design conveyor belt systems that suit the spatial and operational requirements of your facility, including horizontal, inclined, or curved layouts, as well as integrating additional components such as transfer stations, chutes, and gates to streamline your operations further.

- Automation and Control: Incorporate advanced automation and control technologies into your conveyor belt solution, enabling real-time monitoring and adjustments to optimise efficiency, minimise downtime, and adapt to dynamic production requirements.

Improving Efficiency through System Integration and Maintenance

To further enhance efficiency and productivity, integrating your customised conveyor belt solution with your facility’s existing processes and equipment is crucial. Additionally, regular and proactive maintenance is key to ensuring a long-lasting and reliable conveyor belt solution. Best practices include:

- System Integration: Collaborate closely with conveyor belt solution providers throughout the design and implementation process to ensure seamless integration with your facility’s existing production or storage systems, maximising efficiency and minimising disruptions.

- Scheduled Maintenance: Establish a regular maintenance schedule that addresses critical components such as belts, rollers, motors, and electrical systems, ensuring optimal performance and reducing the risk of downtime.

- Proactive Repairs and Replacements: Monitor the wear and tear of conveyor belt components, addressing potential issues through timely repairs or replacements, preventing larger operational disruptions and maintaining peak efficiency.

Case Studies: Customised Conveyor Belt Solutions in Action

To illustrate the transformative potential of customised conveyor belt solutions, let’s explore a few real-world examples of how various industries have successfully addressed their unique challenges through tailored implementations:

- Mining: By opting for a custom-designed, heavy-duty conveyor belt solution capable of handling abrasive materials and harsh environmental conditions, a mining operation successfully increased productivity while mitigating worker safety risks and reducing costly downtime.

- Pharmaceuticals: A pharmaceutical production facility opted for a customised, modular conveyor belt system built with food-grade materials, promoting cleanliness and hygiene during the high-speed processing of delicate drug products.

- Automotive: An automotive manufacturing plant implemented a customised conveyor belt system with advanced automation and control technologies, enabling precise handling of heavy components and intricate assembly processes, ultimately ensuring a smooth and efficient production line.

Conclusion

To truly unlock the efficiency-boosting potential of conveyor belt solutions across diverse industries, it’s essential to take a customised approach that addresses each sector’s unique challenges and requirements. By carefully considering factors such as conveyor belt material, belt type, system configuration, and integration with existing processes, businesses can implement tailored conveyor belt solutions that drive efficiency, productivity, and long-term success.

Change Parts Pty Ltd is your dedicated partner in designing, implementing, and maintaining customised conveyor belt solutions tailored to your industry’s needs. Leverage our experience and expertise to ensure your facility benefits from state-of-the-art conveyor belt systems perfectly aligned with your operational requirements.

Are you looking to boost the efficiency and productivity of your facility’s operations? Look no further than Change Parts Pty Ltd! Our expert team specializes in creating custom conveyor belt solutions tailored to meet the unique needs of your facility. Whether you’re looking to reduce downtime, increase throughput, or simply streamline your production process, our custom conveyor belts can help you achieve your goals. Contact us today to discover how we can create a custom conveyor belt solution that’s perfect for your facility.