Efficient and dependable conveyor belt systems are critical to any successful food manufacturing facility. However, with a vast array of conveyor belt types available, selecting the right one for your specific application can be a daunting task. Understanding the diversity of conveyor belt types and their relevance in various food manufacturing processes allows you to choose the perfect solution for your facility, ensuring optimal productivity and performance.

In this comprehensive guide, we will explore the different types of conveyor belts utilised in food manufacturing facilities, examining their unique attributes, benefits, and suitability for specific production processes. We will discuss popular conveyor belt types such as steel belts, fabric belts, and plastic modular belts, as well as niche solutions catered to specialised applications in the food manufacturing industry. Additionally, this guide will provide invaluable insights on selecting the right conveyor belt type based on throughput demands, hygiene requirements, and ease of maintenance.

Empower yourself with the knowledge to make a well-informed decision on the ideal conveyor belt type for your food manufacturing facility, enhancing operational efficiency, productivity, and long-term success in this competitive industry.

Exploring Popular Conveyor Belt Types

There are numerous conveyor belt options to choose from. To help you make an informed decision, let’s dive into the essential types of conveyor belts commonly used in food manufacturing facilities.

1. Steel Belts

Constructed from stainless steel, steel belts are designed for durability and performance under challenging conditions. Resistant to high temperatures and corrosive environments, steel belts are ideal for heavy-duty and high-temperature food manufacturing processes, such as baking, frying, and transporting abrasive materials. Their ease of cleaning and minimal risk of contamination make them an excellent option for maintaining high hygiene standards in your facility.

2. Fabric Belts

Fabric conveyor belts are made from multiple layers of synthetic fibres, such as polyester or nylon, making them flexible, lightweight, and ideal for a broad range of food manufacturing applications. Fabric belts provide gentle handling of delicate food products, reducing the risk of damage during transportation. With their low-energy requirements, fabric belts are suitable for applications with specific temperature, moisture, or hygiene concerns, such as fresh produce or baked goods handling.

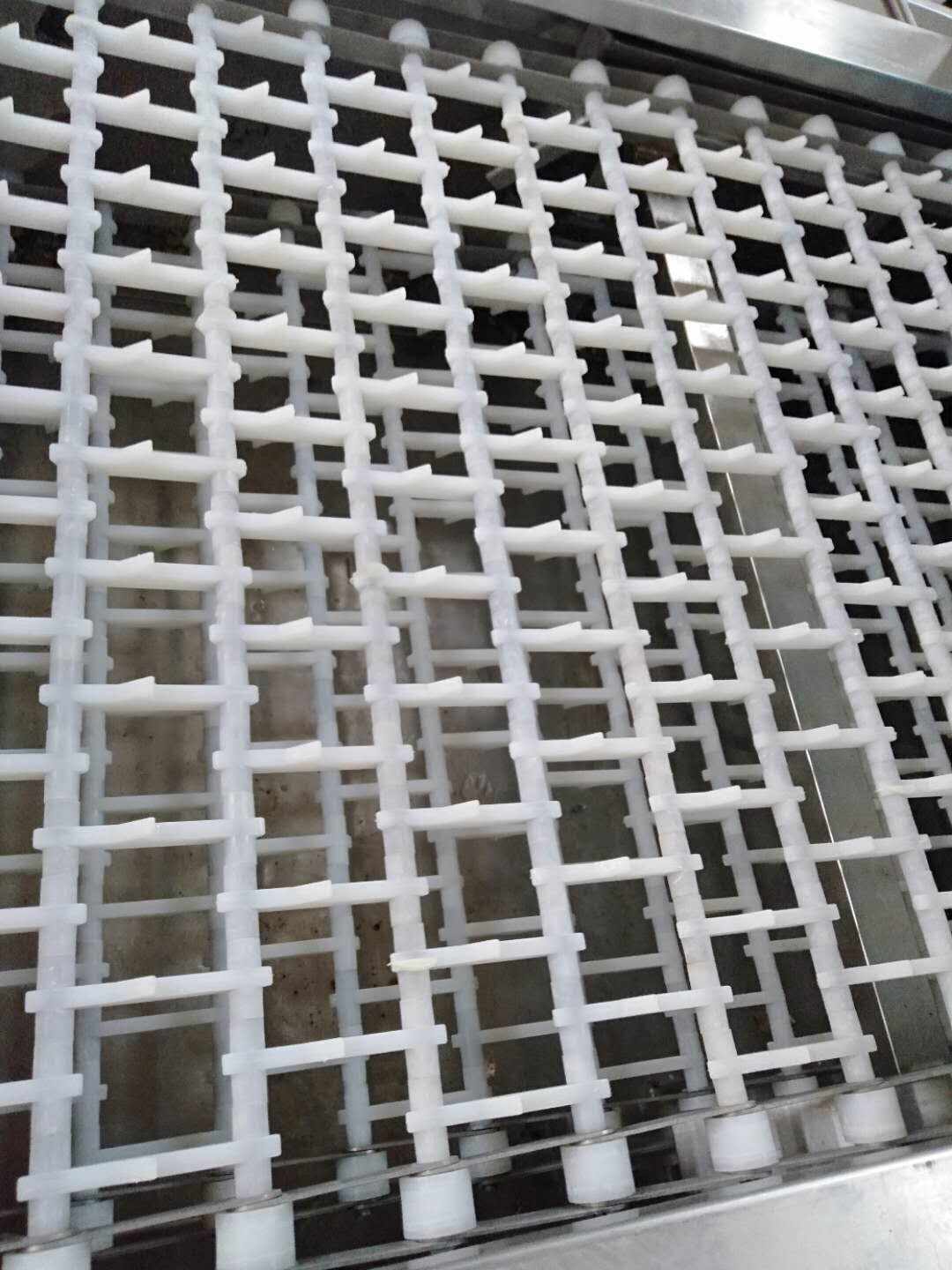

3. Plastic Modular Belts

Comprising interlocking plastic modules, plastic modular belts offer a versatile and adaptable conveyor solution. Their unique modular construction allows for easy repairs and adjustments, reducing downtime and maintenance costs. Plastic modular belts are perfect for diverse food manufacturing processes, including sorting, packaging, and spiral conveyors for cooling or freezing applications. Their easy-to-clean nature and resistance to bacterial growth make them a popular option for maintaining hygiene standards in the food manufacturing industry.

4. Specialty Conveyor Belts

In addition to the main types of conveyor belts, there are several niche solutions specifically designed to cater to unique food manufacturing processes or operational requirements:

- Positive Drive Belts: These belts incorporate a sprocket-driven system that minimises slippage, ensuring consistent product handling in wet or greasy environments.

- Troughed Belts: Ideal for conveying bulk materials such as grains or powders, troughed belts form a U-shaped carrying surface that prevents spillage and maintains product integrity.

Choosing the Right Conveyor Belt for Your Facility

When evaluating conveyor belt types for your food manufacturing facility, consider the following factors to make an informed decision:

1. Production Requirements

Assess your facility’s production requirements, such as throughput demands, processing conditions, and product specifications. For example, facilities handling delicate or perishable food items may require gentle product handling with minimal impact, making fabric belts a suitable option.

2. Hygiene and Sanitation Standards

For food manufacturing facilities, maintaining strict hygiene standards is of paramount importance. Consider conveyor belt options that can uphold cleanliness and prevent contamination. Materials like plastic modular belts and steel belts are easy to clean and sanitise, making them ideal for hygienic applications.

3. Environmental Conditions

Evaluate the environmental conditions where your conveyor belt systems will be operating. Factors like temperature, humidity, and exposure to aggressive chemicals can impact the performance and longevity of conveyor belts. Ensure the chosen conveyor belt type can withstand these conditions without compromising efficiency or product quality.

4. Maintenance Requirements

Consider the maintenance needs of various conveyor belt types and their potential impact on your facility’s productivity. Some conveyor belts may require more frequent servicing or be more susceptible to wear and tear. Weigh the potential for downtime and maintenance costs against each conveyor belt type’s advantages.

Conclusion

Selecting the right conveyor belt type for your food manufacturing facility is crucial for achieving optimal efficiency, productivity, and long-term success. By understanding the range of conveyor belt types and their applications, you can make an informed decision that caters to your unique operational demands, upholds strict hygiene standards, and minimises maintenance requirements.

Partnering with industry-leading suppliers like Change Parts Pty Ltd can provide invaluable expertise, tailored solutions, and premium-quality products designed to enhance your food manufacturing facility’s productivity and long-term growth prospects.

Ready to unlock your food manufacturing facility’s potential with the perfect conveyor belt type? Contact Change Parts Pty Ltd today for expert guidance, customised solutions, and a comprehensive range of high-quality conveyor belts that will elevate your facility’s performance and set you apart in the competitive food manufacturing landscape.