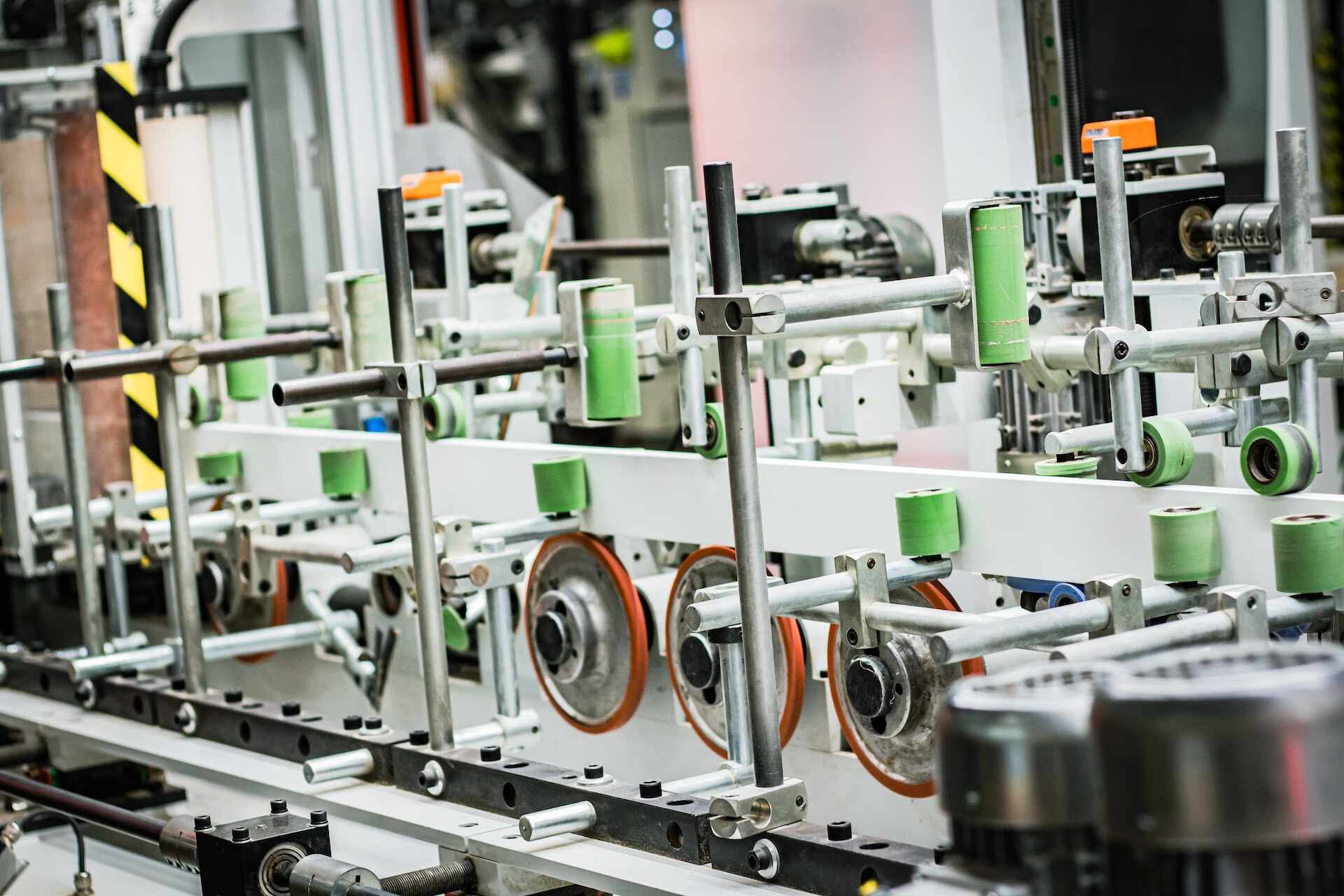

In food manufacturing operations, conveyor belt systems play a critical role in the efficient transport and processing of products. Over time, conveyor belts may begin to wear, sustain damage, or become less effective, leading to a decrease in productivity or an increased risk of product contamination. As a result, it is crucial to determine the most appropriate course of action to maintain the integrity and efficiency of your conveyor belt system: repair or replace?

In this article, we will explore the key factors to consider when deciding whether to repair or replace your conveyor belt in a food manufacturing operation. We will discuss how to effectively assess the condition and performance of your existing conveyor belt system, and the benefits and drawbacks of both repair and replacement. Finally, we will provide guidance on how to make the right decision for your operation, ensuring that you maximise safety, efficiency, and return on investment.

Key Factors to Consider When Evaluating Conveyor Belt Performance

When deciding whether to repair or replace your conveyor belt, consider these key factors to ensure a comprehensive evaluation:

1. Age and Expected Lifespan of Conveyor Belt

Conveyor belts have an expected lifespan that can vary based on factors such as maintenance, stress, and environmental conditions. Assess the age of your conveyor belt in relation to its expected lifespan and weigh this against the costs and benefits of repairing or replacing the belt.

2. Extent of Wear and Damage

Examine the belt for signs of wear, damage, or degradation, such as cracking, abrasion, or delamination. If the damage is concentrated in specific areas or appears to be minor, repair may be a suitable option. However, if damage is widespread or if the belt material has degraded significantly, replacement may be necessary.

3. System Efficiency and Productivity

Evaluate how your conveyor belt system is performing in terms of efficiency and productivity. A conveyor belt that is no longer performing optimally may require repair or replacement to ensure continued productivity and maintain food safety standards.

4. Repair History and Maintenance Costs

Consider the repair history of your conveyor belt, including the number of previous repairs, the cost of repairs, and any recurring issues. Frequent repairs may indicate that the belt is nearing the end of its useful life and replacement may be more cost-effective in the long run.

Repair Versus Replacement: Pros and Cons

To make a well-informed decision regarding the repair or replacement of your conveyor belt, it is essential to evaluate the pros and cons of both options:

Repair Pros:

– More affordable in the short term, especially if the damage is minor or if repairs can be completed in-house.

– Faster turnaround time, allowing for minimal downtime and disruption to your food manufacturing operation.

– Environmentally friendly, as repairing the belt can extend its life and reduce waste.

Repair Cons:

– Repair work may not resolve the underlying issue, leading to repeat repairs and potential downtime.

– A repaired belt may not perform at the same level as a new belt, resulting in potential productivity losses.

– Repairs may not be suitable for widespread, severe, or recurring damage.

Replacement Pros:

– New conveyor belts can offer improved performance and efficiency, contributing to enhanced productivity.

– Replacing a worn or damaged belt can help prevent unexpected breakdowns and reduce maintenance costs.

– A new belt can ensure compliance with food safety standards and minimise the risk of product contamination.

Replacement Cons:

– Higher initial cost compared to repairing the existing belt.

– Longer downtime for installation and integration with your existing equipment and processes.

Making the Right Decision for Your Operation

When deciding between repairing and replacing your conveyor belt, it’s essential to consider your operation’s unique circumstances. The following guidance can help inform your decision-making process:

1. Consult with Conveyor Belt Solution Providers

Seek advice from experienced conveyor belt solution providers, like Change Parts Pty Ltd, to discuss options for repair or replacement. They can help you assess the condition of your existing belt, provide recommendations based on your operation’s needs, and offer cost-effective solutions.

2. Analyse the Costs and Benefits

Determine the short-term and long-term costs of repairing or replacing your conveyor belt, taking into account factors such as repair costs, system downtime, productivity, and expected lifespan. Weigh these costs against the potential benefits of improved performance, efficiency, and food safety compliance.

3. Prioritise Food Safety and Compliance

In food manufacturing, maintaining strict food safety standards is paramount. Ensure that your decision prioritises compliance with food safety regulations and minimises the risk of product contamination.

Conclusion

Deciding whether to repair or replace your conveyor belt in food manufacturing is a critical decision that can impact the efficiency, productivity, and safety of your operation. By carefully weighing the pros and cons of repair versus replacement, considering key factors such as belt age, wear, system efficiency, and maintenance costs, and consulting with experienced conveyor belt solution providers, like Change Parts Pty Ltd, you can make the most informed decision for your unique circumstances.

Partner with Change Parts Pty Ltd for industry-leading expertise and tailored conveyor belts designed to meet your food manufacturing requirements. Contact our team today to discuss whether repair or replacement is the right choice for your operation.