Selecting the appropriate conveyor belt for your food manufacturing operation is a critical decision that significantly impacts efficiency, productivity, and food safety compliance. With a wide range of conveyor belt options available, it is essential to consider factors such as material, design, regulatory compliance, and maintenance requirements to make informed choices that best support your specific food manufacturing processes.

In this comprehensive guide, we will explore the key aspects involved in selecting the ideal conveyor belt for your food manufacturing application. We’ll examine essential criteria, such as the different materials available in the market, including rubber and stainless steel, and how they can impact your operation. Additionally, we’ll delve into the characteristics of various conveyor belt designs, covering elements such as flat belts, modular belts, and wire mesh belts, among others, highlighting their respective benefits and suitability for particular food applications. Furthermore, we will provide insights into ensuring compliance with food safety regulations and discuss how ease of maintenance can play a crucial role when evaluating conveyor belts for your specific food manufacturing requirements.

Understanding the Different Conveyor Belt Materials

The choice of material for your conveyor belt system is of utmost importance, as it directly affects the performance, durability, and food safety compliance of your food manufacturing operation. The primary materials used in the industry include rubber and stainless steel:

1. Rubber Conveyor Belts: Rubber conveyor belts are highly flexible and provide excellent grip. They are well suited for food packaging or handling applications where product positioning is crucial. However, they may be less resistant to heat, chemicals, or abrasion as compared to stainless steel belts.

2. Stainless Steel Conveyor Belts: Stainless steel belts are known for their exceptional durability, resistance to corrosion, and suitability for high-temperature environments. They offer easy-to-clean surfaces that aid in maintaining hygiene and food safety standards. This material is ideal for food manufacturing processes that require high degrees of ventilation, drainage, or moisture removal.

Selecting the Right Belt Design for Your Application

Once you have determined the preferred conveyor belt material for your operation, it’s vital to consider different design options to cater to your specific food manufacturing system:

1. Flat Belts: Flat belts offer a simple design and are highly effective for low-capacity applications, making them suitable for transporting lightweight products with even surfaces. These belts are easy to clean and maintain, which is vital for food safety and hygiene.

2. Modular Belts: Modular belts are constructed from individual interlocking plastic modules, allowing for easy repair and replacement of damaged sections without requiring the complete removal of the belt. These belts are highly versatile and can easily navigate around corners or curves, making them suitable for complex food manufacturing lines.

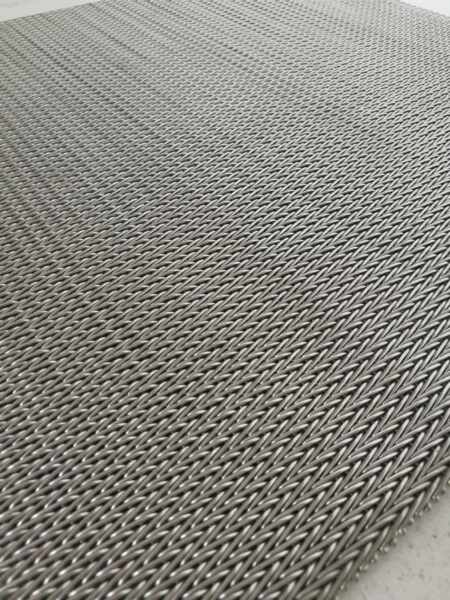

3. Wire Mesh Belts: Wire mesh belts are manufactured from interwoven steel wires, providing excellent heat resistance and a high degree of ventilation. They are well suited for food manufacturing applications involving baking, drying, or even freezing processes.

Considering Food Safety Compliance

When selecting a conveyor belt for your food manufacturing operation, ensuring compliance with food safety requirements is of utmost importance:

1. Easy Cleaning and Sanitation: The conveyor belt should be easy to clean and sanitise, with minimal areas for debris or contaminants to collect. This will help maintain food quality and safety while reducing downtime and labour costs associated with cleaning procedures.

2. Compliance with Regulations: Ensure that the chosen conveyor belt complies with all relevant food safety regulations and industry standards, such as FDA, USDA, and HACCP guidelines.

3. Prevention of Cross-Contamination: Select a conveyor belt that effectively reduces the risk of cross-contamination between production runs and various food products to guarantee the highest quality and safety for consumers.

Evaluating Maintenance Requirements

Lastly, don’t overlook the maintenance requirements of your conveyor belt, as they can have a significant impact on the overall efficiency and performance of your food manufacturing operation:

1. Inspections and Repairs: Regular inspections of your conveyor belt system will help identify potential issues before they escalate into larger problems or production disruptions. Make sure to address any wear and tear, misalignment, or other inefficiencies promptly to maintain optimal system performance.

2. Preventative Maintenance: Implement a routine preventative maintenance schedule to keep your conveyor belt system in top condition. This may include tasks such as lubrication, adjustments, and tensioning to ensure the longevity and optimal performance of your conveyor belt.

3. Spare Parts and Replacement: Keep a stock of spare parts and components for your conveyor belt system readily available, enabling you to quickly address any issues that may arise without extensive downtime.

Conclusion

Choosing the right conveyor belt for your food manufacturing operation is pivotal in ensuring optimal efficiency, productivity, and food safety standards. By considering the various aspects described in this guide, including material choice, design, food safety compliance, and maintenance requirements, you can confidently select the most appropriate conveyor belt solution tailored to your unique food manufacturing processes.

Don’t let conveyor belt selection impede your food manufacturing operation’s success. Reach out to Change Parts Pty Ltd for expert guidance, exceptional conveyor belts, and comprehensive support, empowering you to make the best possible choice for your specific needs and achieve operational excellence in the dynamic food manufacturing sector.