Conveyor belt systems play an essential role in numerous industries by facilitating the smooth transportation of materials from one point to another within a facility. With many conveyor belt types available, businesses can tailor their systems to suit specific applications and requirements.

One such conveyor belt type is the Balanced Weave Chain Drive Belt, which offers a combination of strength, flexibility, and versatility, making it a popular choice across various sectors. This article will provide an in-depth look into the Balanced Weave Chain Drive Belt, its applications, benefits, and tips for proper maintenance to ensure optimal performance and longevity.

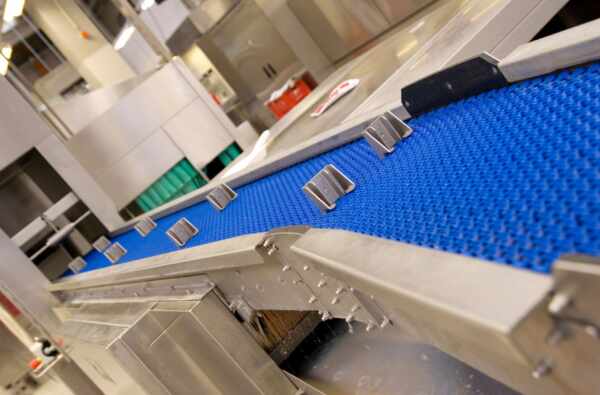

The Balanced Weave Chain Drive Belt is a type of conveyor belt featuring a balanced weave configuration that consists of alternating right and left-hand spirals connected by a crimped cross rod. The belt is designed to be driven by sprockets connected to the chain, which helps to minimise belt slippage and improve tracking. This design allows the belt to provide a strong, stable, and flexible surface for transporting materials, making it well-suited to a variety of applications.

Some of the industries in which the Balanced Weave Chain Drive Belt is commonly employed include manufacturing, food processing, automotive, aerospace, and packaging, among others. Its ability to handle high temperatures and challenging environments makes it an ideal choice for heat treatment processes, such as furnace operations, as well as applications that involve exposure to chemicals or abrasive materials.

A notable advantage of the Balanced Weave Chain Drive Belt is its capacity to handle diverse load sizes and weights, allowing it to adapt to various transport requirements within a facility. Moreover, the belt’s inherent flexibility facilitates smooth navigation around curves and obstacles, contributing to an efficient and versatile conveyor system.

To ensure the Balanced Weave Chain Drive Belt continues to perform at its best, proper maintenance is essential. Regularly inspecting the belt for signs of wear and damage, such as broken spirals or frayed edges, can help extend its lifespan and maintain optimal functionality. Additionally, maintaining proper tension, alignment, and lubrication is crucial in preventing unnecessary wear and tear.

In this comprehensive guide, we will explore various aspects and applications of the Balanced Weave Chain Drive Belt further, delving into the benefits it offers and the essential maintenance steps required to keep your conveyor system running efficiently.

Applications of the Balanced Weave Chain Drive Belt

Heat Treatment Processes and Furnace Operations

The Balanced Weave Chain Drive Belt is an excellent choice for heat treatment processes in various industries, such as metalworking, glass manufacturing, and ceramics production. Its strong construction allows it to withstand high temperatures, making it suitable for use in furnaces and ovens. Furthermore, the balanced weave design ensures even heat distribution and proper ventilation, resulting in consistent product quality throughout the heating process.

Food Processing and Packaging

The food industry presents unique challenges when it comes to conveyor belt systems, with hygiene and sanitation being top priorities. The Balanced Weave Chain Drive Belt’s design facilitates easy cleaning and maintenance. Additionally, its robust construction makes it an ideal choice for applications where exposure to moisture or chemicals is common, such as in food processing and packaging facilities. The belt can be used for operations like baking, cooling, and washing, and can handle food products of various sizes and weights.

Aerospace and Automotive Manufacturing

Production environments in aerospace and automotive manufacturing can often involve heavy loads, high speeds, and complex routes. The Balanced Weave Chain Drive Belt’s flexibility, strength, and ability to handle a wide range of loads make it well-suited for these applications. With precise tracking and minimal slippage, it ensures that parts and materials are transported accurately and efficiently throughout the production process.

Packaging and Distribution

In packaging and distribution centres, conveyor belts need to accommodate varying product sizes, weights, and shapes. The Balanced Weave Chain Drive Belt’s adaptable design allows it to meet these diverse requirements, making it the ideal choice for transporting goods within a facility or between different stages of processing. Its ability to handle turns and inclines adds to its versatility in complex facilities where space constraints or obstacles may be present.

Benefits of the Balanced Weave Chain Drive Belt

High Load-Bearing Capacity

One key advantage of the Balanced Weave Chain Drive Belt is its ability to handle various load sizes and weights. This makes it a versatile choice for industries with diverse material handling requirements, ensuring that the belt can adapt to changes in production processes or the introduction of new products.

Increased Flexibility

The construction of the Balanced Weave Chain Drive Belt enables it to navigate turns and inclines with ease, while still maintaining accurate tracking. This flexibility allows it to fit seamlessly into complex conveyor systems with winding routes or limited space.

Minimal Belt Slippage

The chain drive design of the belt ensures proper engagement with sprockets, reducing the likelihood of belt slippage. This leads to improved efficiency and reduced downtime, as the likelihood of materials falling off the belt or causing jams is minimised.

Resistance to Wear and Tear

The Balanced Weave Chain Drive Belt’s robust construction enables it to withstand harsh working conditions, such as exposure to high temperatures, chemicals, or abrasive materials. This durability helps extend the belt’s lifespan while maintaining optimal performance.

Maintaining Your Balanced Weave Chain Drive Belt

Regular Inspections

To ensure the longevity and optimal functionality of your Balanced Weave Chain Drive Belt, it’s essential to perform regular inspections. Check for signs of wear and tear, such as broken spirals, frayed edges, or damage to the chain drive. Addressing these issues promptly can help extend the belt’s lifespan and prevent costly downtime.

Proper Tension

Maintaining the appropriate tension on your Balanced Weave Chain Drive Belt is critical in preventing wear and tear. Over-tensioning can lead to premature wear and damage, while under-tensioning can cause tracking issues. It’s important to follow the manufacturer’s recommendations for proper tensioning in order to maintain optimal belt performance.

Alignment and Tracking

Ensuring proper alignment and tracking of your Balanced Weave Chain Drive Belt is crucial in preventing unnecessary wear. Make sure that the belt is running smoothly and engaging correctly with sprockets. Misalignment and tracking issues should be addressed immediately to prevent damage to the belt and reduce the risk of downtime.

Lubrication

Lubricating the chain drive on your Balanced Weave Chain Drive Belt is an essential maintenance step to reduce friction and wear. Follow the manufacturer’s guidelines for proper lubrication to keep your belt running smoothly and extend its lifespan.

Maximising the Performance of Your Balanced Weave Chain Drive Belt

The Balanced Weave Chain Drive Belt offers a combination of strength, flexibility, and versatility, making it a popular choice across various industries. By understanding its applications, benefits, and maintenance requirements, you can maximise the performance of your belt and ensure the smooth operation of your conveyor system.

Investing in the right conveyor belt type and committing to proper maintenance will not only improve the efficiency of your facility but also contribute to the overall success of your industry operations. Get in touch with the team of Change Parts Pty Ltd for more information.