The need for robust, reliable, and versatile solutions in industrial conveyor belts continues to grow, particularly for industries with demanding product handling requirements. One type of belt that stands out in this regard is the Heavy Duty – Combination Belt, known for its impressive strength and adaptability. This comprehensive guide will cover the unique benefits of Heavy Duty – Combination Belts, potential applications across various industries, and crucial maintenance practices for optimal performance and durability.

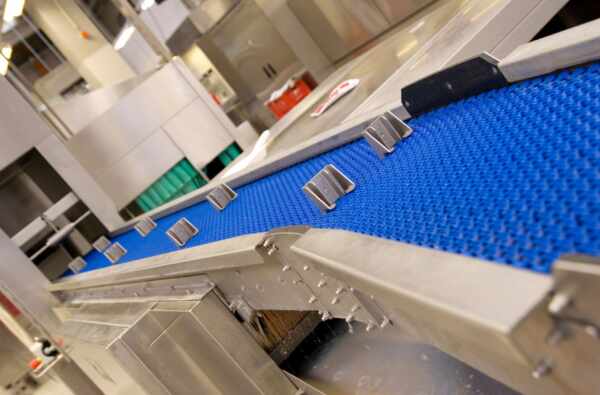

Heavy Duty – Combination Belts are designed to withstand the challenges of demanding industrial environments while providing consistent and efficient product transportation. These belts feature a combination of flat wire spirals interwoven with heavy-duty connecting rods, providing enhanced strength and durability compared to standard conveyor belts. This sturdy construction can handle substantial loads, making Heavy Duty – Combination Belts ideal for transporting heavy or bulky products.

One of the primary advantages of Heavy Duty – Combination Belts is their versatility, as they can be customised to fit the specific needs of your conveyor system. The belts can be designed with different mesh openings to accommodate varying product sizes and weights, while optional features such as side flights or edge guards can enhance the belt’s performance and adaptability.

Industries where Heavy Duty – Combination Belts excel include mining, foundries, construction materials processing, and general heavy-duty manufacturing. Due to their robust construction and ability to handle substantial loads, these belts are well-suited to applications involving the transportation of heavy materials or machinery components.

Ensuring the longevity and efficiency of your Heavy Duty – Combination Belt is contingent upon proper maintenance. Regular inspections, appropriate tension adjustments, thorough cleaning, and necessary component replacements are all vital to optimising your belt’s performance and extending its service life.

In this guide, we will explore the world of Heavy Duty – Combination Belts in-depth, shedding light on their unique features, suitable industries and applications, and maintenance best practices. With this knowledge, you will be better equipped to make informed decisions regarding your conveyor system and optimise the performance of your Heavy Duty – Combination Belt.

Unique Features and Benefits of Heavy Duty – Combination Belts

Enhanced Strength and Durability

Heavy Duty – Combination Belts are designed to provide superior strength and durability compared to standard conveyor belts. With their flat wire spirals interwoven with heavy-duty connecting rods, these belts offer the support necessary to handle substantial loads efficiently, making them ideal for transporting heavy or bulky products.

Versatility and Customisation

One of the primary advantages of Heavy Duty – Combination Belts is their versatility, as they can be customised to meet the specific needs of your conveyor system. The belts can be designed with different mesh openings to accommodate a wide range of product sizes and weights, while optional features such as side flights or edge guards can further enhance the belt’s performance and adaptability.

Reduced Downtime

Due to their robust construction, Heavy Duty – Combination Belts are capable of withstanding demanding working conditions, reducing the risk of unexpected breakdowns and associated downtime. This resilience ensures your conveyor system remains operational, maintaining productivity and minimising costs.

Suitable Industries and Applications for Heavy Duty – Combination Belts

Mining Industry

In the mining industry, Heavy Duty – Combination Belts excel at transporting heavy loads of raw materials, such as coal, minerals, and ores. Their robust construction and ability to handle substantial weights make them the ideal choice for the harsh and demanding conditions found in mining operations.

Foundries and Metal Processing

Heavy Duty – Combination Belts are commonly used in foundries and metal processing facilities for transporting large, heavy metal components and castings. Their impressive strength ensures that they can handle the substantial loads and abrasive materials typically encountered in these environments.

Construction Materials Processing

In construction materials processing facilities, Heavy Duty – Combination Belts are integral to the transportation of large, heavy products and materials such as concrete blocks, bricks, and tiles. The belts’ resilience and adaptability make them an excellent fit for this demanding industry, ensuring that your conveyor system operates efficiently and consistently.

General Heavy-Duty Manufacturing

Heavy Duty – Combination Belts can also be used in general manufacturing facilities that require the transportation of large, heavy products or machinery components. The robust construction of these belts enables them to handle a variety of applications in demanding industrial environments while maintaining efficiency and operational reliability.

Essential Maintenance Tips for Heavy Duty – Combination Belts

Regular Inspections

To prolong the lifespan and ensure the optimal performance of your Heavy Duty – Combination Belt, it is vital to conduct regular inspections. Look for signs of wear or damage, such as deformed spirals, worn connecting rods, or damaged mesh openings, and address these issues promptly to avoid costly downtime and extend the belt’s service life.

Appropriate Tension Adjustments

Maintaining the proper tension in your Heavy Duty – Combination Belt is crucial to its overall performance and longevity. By following the manufacturer’s recommendations on tension adjustments, you can prevent belt slippage and tracking issues, ensuring smooth and efficient operation.

Thorough Cleaning

Keeping your Heavy Duty – Combination Belt clean is essential to maintaining its efficiency and reliability. Regular cleaning will prevent dirt, debris, and other contaminants from accumulating, which can negatively impact the belt’s performance and product handling. Use an appropriate cleaning solution and techniques for your specific belt material and application to ensure successful cleaning while avoiding damage to the belt.

Component Replacement

Over time, components of your Heavy Duty – Combination Belt may wear and require replacement. By monitoring the belt’s condition and replacing worn parts as necessary, you can maintain the performance and efficiency of your conveyor system, reducing the risk of unexpected breakdowns and downtime.

Elevate Your Conveyor System with a Heavy Duty – Combination Belt

Heavy Duty – Combination Belts offer numerous features and benefits that make them an ideal choice for a wide range of demanding industrial applications. By understanding the unique advantages of these belts, implementing them in suitable industries and applications, and adhering to essential maintenance practices, you can ensure optimal efficiency, reliability, and longevity for your conveyor system.

Whether you work in mining, foundries, construction materials processing, or general heavy-duty manufacturing, investing in Heavy Duty – Combination Belts and maintaining them properly will help you achieve efficient, effective, and dependable product transportation within your facilities. Embrace the power of Heavy Duty – Combination Belts from Change Parts Pty Ltd and unlock a new level of performance for your conveyor system.