The heart of any food manufacturing facility lies in the conveyor belt systems that facilitate the smooth flow of ingredients, products, and packaging throughout the production line. The right conveyor belt system can significantly impact your facility’s efficiency, productivity, and adherence to food safety standards. Therefore, selecting an appropriate conveyor belt is a critical decision for food manufacturers. With multiple types of conveyor belts available, it’s essential to consider various factors, such as materials, temperature conditions, and hygiene requirements, when selecting the best fit for your unique process.

In this detailed guide, we will guide you through the key considerations when choosing the ideal conveyor belt for your food manufacturing facility, while discussing the uniqueness and advantages of different conveyor belt types like steel belts, modular belts, fabric belts, and positive drive belts. Each belt type comes with its benefits and drawbacks, and identifying the one that fulfils your specific requirements will facilitate increased efficiency and a more streamlined production process.

Diving deep into factors like product characteristics, temperature conditions, moisture and humidity, cleaning and sanitation requirements, and line speed and efficiency, we will provide insights and advice to help you select the perfect conveyor belt system tailored to your food manufacturing process. We will also touch on the importance of collaborating with trusted conveyor belt suppliers and industry experts, like Change Parts Pty Ltd, to offer guidance, support, and a comprehensive range of conveyor belt solutions suited to your needs.

Investing in the right conveyor belt system for your food manufacturing facility can transform your production line’s performance, reduce downtime, and enforce strict hygiene standards crucial for the success and longevity of your business.

Conveyor Belt Selection: Key Considerations for Food Manufacturers

Understanding Different Conveyor Belt Types

Before we delve into the selection criteria for choosing an appropriate conveyor belt, let’s explore the most common types used in food manufacturing facilities and their unique features:

1. Steel belts: Known for their strength and durability, steel belts are ideal for heavy-duty applications, high-temperature conditions, and processes involving abrasive materials. Their robust construction ensures a long service life and minimal maintenance requirements.

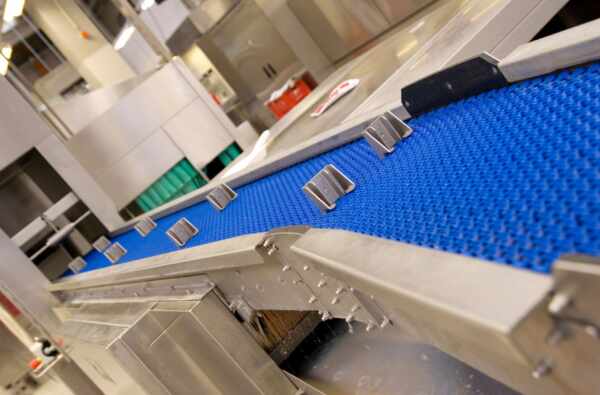

2. Modular belts: With their interlocking design, modular belts offer flexibility, easy repair, and excellent product support. These belts are typically constructed from plastic materials, making them easy to clean and suitable for a wide range of food manufacturing processes.

3. Fabric belts: Fabric belts are lightweight, versatile, and suitable for a variety of applications, including general food handling, processing, and packaging. They can be customised with various coatings, textures, and finishes depending on the specific requirements of the food manufacturing process.

4. Positive drive belts: Designed for efficient and precise product movement, positive drive belts feature an innovative design that ensures consistent tension and optimum tracking. These belts are often utilised in applications requiring precise positioning and smooth, high-speed operation.

Key Considerations for Conveyor Belt Selection

Now that we’ve highlighted some of the primary conveyor belt types, let’s go through the critical factors you need to consider when selecting the right conveyor belt system for your food manufacturing facility:

1. Product Characteristics

Consider the unique characteristics of the food products your facility processes, such as size, shape, weight, and texture. These factors will impact the type of conveyor belt best suited for your application:

– For delicate products: A smooth, cushioned belt material will help prevent damage or bruising.

– For sticky or oily products: A belt with a non-stick surface or easy release property will prevent product contamination and minimise cleaning requirements.

2. Temperature Conditions

Temperature plays a key role in your conveyor belt’s selection, as different belts are designed to handle varying temperature ranges:

– For high-temperature processes: Opt for heat-resistant materials like steel or specialised fabric belts.

– For low-temperature or cold storage applications: Choose belts designed to maintain flexibility and performance in freezing conditions.

3. Moisture and Humidity

Factors like moisture and humidity can impact the performance, hygiene, and longevity of your conveyor belt:

– For wet processes and damp environments: Select belt materials resistant to water, mould, and bacterial growth, such as plastic modular belts or sealed-edge fabric belts.

– For dry environments: Fabric belts and steel belts may be more appropriate, as they can better withstand static electricity build-up.

4. Cleaning and Sanitation Requirements

In food manufacturing, maintaining strict sanitation standards is crucial:

– For stringent hygiene requirements: Choose conveyor belts with easy-to-clean materials and designs that minimise crevices where debris can accumulate, such as modular belts or positive drive belts.

– For facilities with less demanding sanitation: Fabric belts or steel belts may suffice, provided they are appropriately coated or treated to meet food safety guidelines.

5. Line Speed and Efficiency

Your production line’s speed and efficiency requirements will influence your conveyor belt selection:

– For high-speed applications: Positive drive belts or steel belts can offer the necessary strength and support for fast, efficient movement.

– For slower or lower-stress applications: Fabric belts or modular belts may provide sufficient performance while delivering lower costs and easier maintenance.

Collaborating with Conveyor Belt Experts

The process of selecting the right conveyor belt for your food manufacturing facility can be complicated. Partnering with industry experts, like Change Parts Pty Ltd, ensures that the conveyor belt system you choose is tailor-made for your specific needs, enhancing productivity, efficiency, and food safety.

Renowned experts can not only guide you in making informed decisions but also provide access to high-quality products and essential services like installation, maintenance, and troubleshooting support. By investing in a collaborative relationship with an expert conveyor belt partner, you can gain the assurance that your facility’s conveyor belt system is perfectly suited for your unique food manufacturing requirements.

Conclusion

Being aware of the various conveyor belt types and their unique features forms the cornerstone of making an informed choice for your food manufacturing facility. By considering factors like product characteristics, temperature conditions, moisture and humidity, cleaning and sanitation requirements, and line speed and efficiency, you can select the ideal conveyor belt system for your production process.

Collaborating with reliable conveyor belt suppliers and experts like Change Parts Pty Ltd can help you maximise the efficiency, productivity and longevity of your conveyor belt systems, ensuring long-term success for your food manufacturing facility.

If you’re ready to explore the ideal conveyor belt solution for your food manufacturing requirements, contact Change Parts Pty Ltd today. With our expert guidance, quality products, and tailored support, we’re committed to helping your business thrive.